El significant skill gap in manufacturing continues to widen, as underscored by Deloitte’s research, which found that 2.1 million unfilled jobs will result in a cost of roughly $1 trillion to the United States in 2030 Solo. Sabemos que existen diversas razones para la falta de talento actual y futura, principalmente debido al envejecimiento de la fuerza laboral, los avances tecnológicos con habilidades que no se mantienen al día y una visión anticuada de lo que significa un puesto en la industria manufacturera. que recuerdan las condiciones de trabajo peligrosas y poco glamorosas que se muestran en “La jungla” del novelista estadounidense Upton Sinclair.

Según el Cámara de Comercio de los Estados Unidos, El 45 por ciento de las vacantes de empleo en el sector manufacturero siguen sin cubrirse. El Futuro del Empleo 2023 del Foro Económico Mundial report highlights that 40 of the current skill requirements in advanced manufacturing are expected to evolve over the next five years. Leaders have sounded the alarm, according to a survey by the Asociación Nacional de Fabricantes (NAM)Casi el 75 por ciento de los gerentes de fabricación citaron la escasez de mano de obra calificada como su principal desafío empresarial.

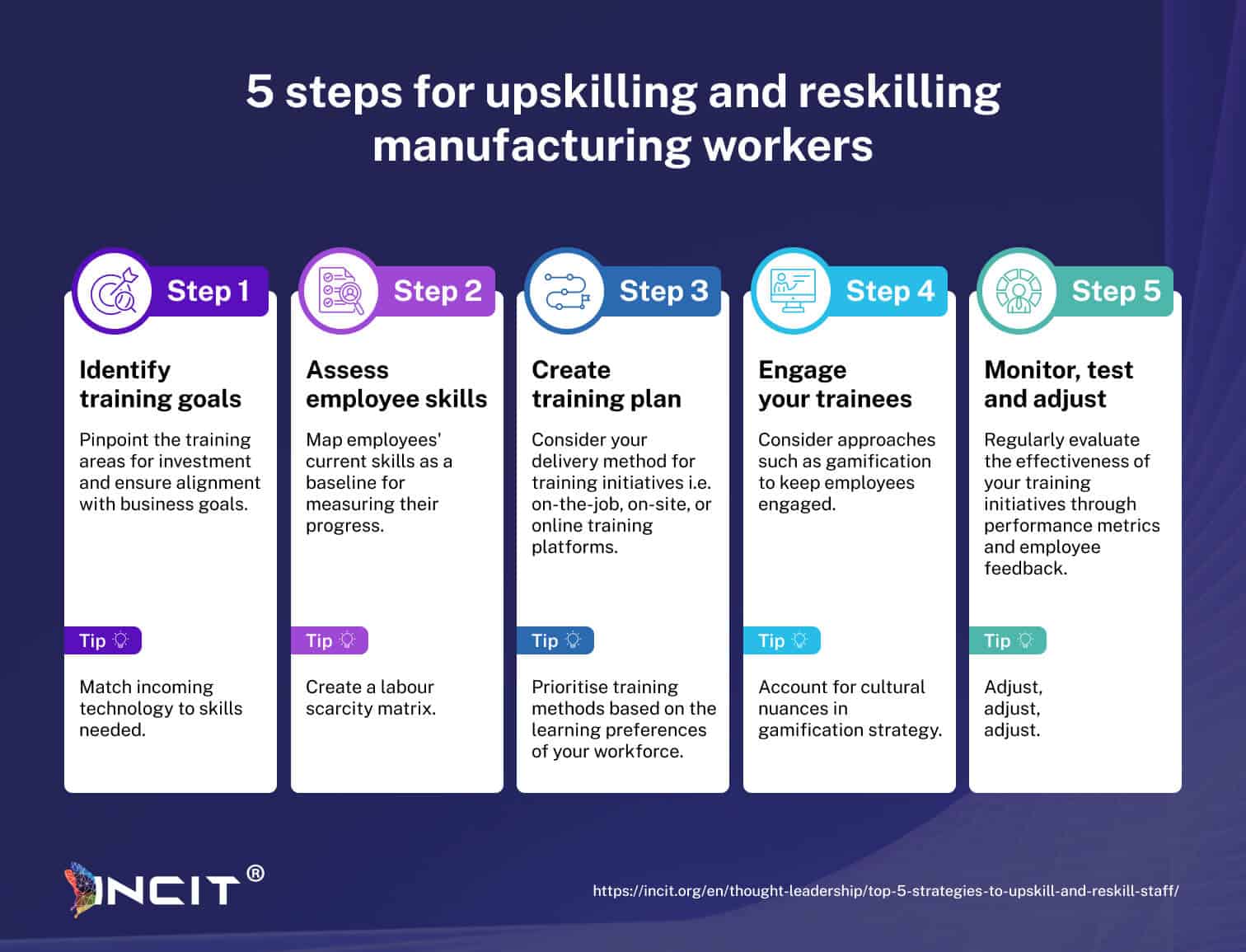

Manufacturers are grappling with a significant labour shortage that demands urgent attention, but what can businesses do to prepare for the looming talent crisis? Below, we explore the key steps to put for empowering workers through targeted upskilling programs, ensuring resilience and growth in the face of workforce challenges.

Fomentar una fuerza laboral preparada para el futuro mediante iniciativas estratégicas de capacitación

Labour shortages in the manufacturing sector are now endemic and expected to worsen. It is imperative for manufacturing companies to invest in upskilling and reskilling initiatives. By implementing targeted training programs aligned with evolving job roles and leveraging innovative methods like gamification (use it to make the reskilling more engaging!), manufacturers can empower their workforce to adapt, thereby alleviating labour shortfalls in the business. Embracing these strategies will not only bridge the skills gap but also position manufacturing firms for sustained growth and competitiveness in the global market.

Además, se ofrecen programas de formación especializados, como el SIRI/COSIRI Programa offered by INCIT, can support leaders with their ongoing skill development with this certification, which advances digitalisation and sustainability practices within manufacturing. Embracing these strategies will not only bridge the skills gap but also position manufacturing firms for sustained growth and competitiveness in the global market.

Frequently Asked Questions About Upskilling and Reskilling in Manufacturing

What Are the 4 Strategies for Upskilling and Reskilling?

The four key strategies for upskilling and reskilling in manufacturing are:

- On-the-job training

- Digital learning platforms

- Industry-academic partnerships

- Certification programs

These approaches help workers gain new skills for smart manufacturing and Industry 4.0.

Why is Upskilling Important in Manufacturing?

Upskilling is important in manufacturing because it helps workers adapt to new technologies, improve productivity, and stay competitive in a rapidly changing Industry 4.0 environment.

What is the Difference Between Upskilling and Reskilling in Manufacturing?

Upskilling means learning new skills to grow in a current role, while reskilling involves training workers for entirely new roles. Both are essential in manufacturing to support digital transformation and automation.

How Can Manufacturers Create a Future-ready Workforce?

Manufacturers can create a future-ready workforce by investing in continuous training, embracing digital tools, building learning cultures, and aligning workforce development with Industry 4.0 technologies.

What Challenges Do Manufacturers Face in Workforce Training?

Manufacturers face challenges like limited training budgets, lack of digital literacy, ageing workforces, and difficulty keeping pace with fast-changing technologies in smart manufacturing.

What Are Examples of Upskilling in Smart Manufacturing?

Examples of upskilling in smart manufacturing include training workers to use robotics, data analytics tools, digital twins, IoT platforms, and AI-based production systems.

How Does Industry 4.0 Affect Workforce Planning?

Industry 4.0 affects workforce planning by shifting the demand toward tech-savvy roles, requiring new skills, and pushing manufacturers to rethink training, hiring, and talent retention strategies.

What Are the Best Practices for Workforce Transformation in Manufacturing?

Best practices for workforce transformation include skills gap assessments, personalised learning paths, leadership development, partnerships with tech providers, and performance tracking tied to Industry 4.0 goals.