De De aanzienlijke kloof tussen vaardigheden in de maakindustrie blijft groeien, zoals blijkt uit onderzoek van Deloitte, waaruit bleek dat 2,1 miljoen onvervulde banen zullen resulteren in kosten van ongeveer $1 biljoen voor de Verenigde Staten. in 2030 We weten dat er verschillende redenen zijn voor het huidige en toekomstige gebrek aan talent, voornamelijk als gevolg van een vergrijzende beroepsbevolking, technologische vooruitgang met vaardigheden die niet gelijke tred houden, en een verouderde kijk op hoe een rol in de productie eruitziet. doet denken aan de gevaarlijke, weinig glamoureuze werkomstandigheden die worden afgebeeld in “The Jungle” van de Amerikaanse romanschrijver Upton Sinclair.

Volgens de Amerikaanse Kamer van Koophandel, 45 procent van de vacatures in de maakindustrie blijft onvervuld. De toekomst van banen van het Wereld Economisch Forum in 2023 Het rapport benadrukt dat 40 van de huidige vaardigheidsvereisten in de geavanceerde productie naar verwachting de komende vijf jaar zullen evolueren. Leiders hebben de alarmbel geluid, volgens een onderzoek van de Nationale Vereniging van Fabrikanten (NAM)bijna 75 procent van de managers in de productiesector noemde het tekort aan geschoolde arbeidskrachten als hun grootste uitdaging.

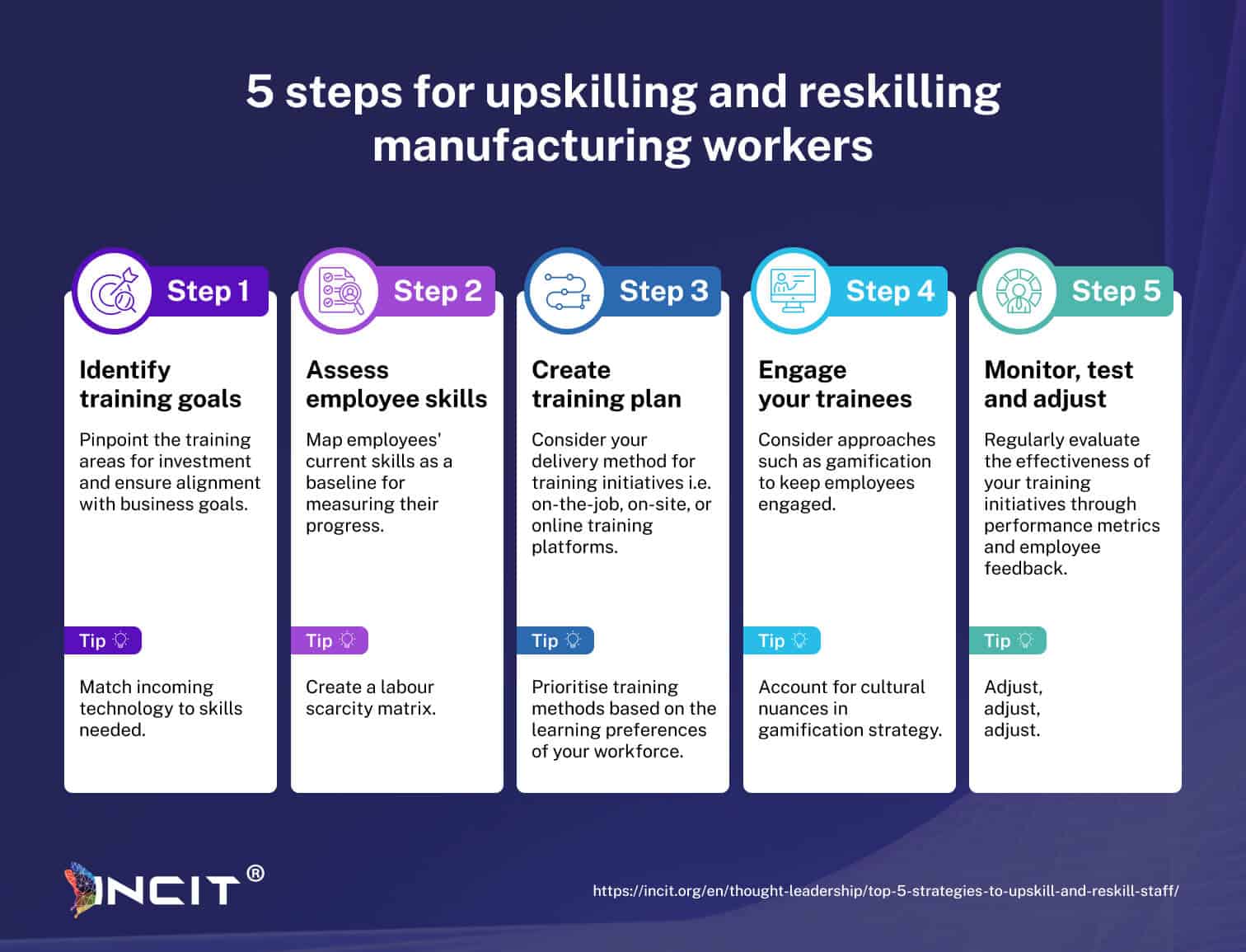

Fabrikanten worstelen met een aanzienlijk tekort aan arbeidskrachten dat dringend aandacht vereist, maar wat kunnen bedrijven doen om zich voor te bereiden op de dreigende talentencrisis? Hieronder bespreken we de belangrijkste stappen om werknemers te empoweren via gerichte bijscholingsprogramma's, waarmee veerkracht en groei worden gewaarborgd in het licht van de uitdagingen op de arbeidsmarkt.

Het bevorderen van toekomstbestendige beroepsbevolkingen door middel van strategische bijscholingsinitiatieven

Het tekort aan arbeidskrachten in de maakindustrie is nu wijdverspreid en zal naar verwachting toenemen. Het is cruciaal dat maakbedrijven investeren in bij- en omscholingsinitiatieven. Door gerichte trainingsprogramma's te implementeren die aansluiten op veranderende functies en innovatieve methoden zoals gamification te benutten (gebruik dit om de omscholing aantrekkelijker te maken!), kunnen fabrikanten hun personeel in staat stellen zich aan te passen en zo het tekort aan arbeidskrachten binnen het bedrijf te verlichten. Door deze strategieën te omarmen, wordt niet alleen de vaardigheidskloof gedicht, maar worden maakbedrijven ook gepositioneerd voor duurzame groei en concurrentievermogen op de wereldmarkt.

Bovendien zijn er gespecialiseerde trainingsprogramma's, zoals de SIRI/COSIRI Programma aangeboden door AANZETTENKan leiders ondersteunen bij hun voortdurende vaardigheidsontwikkeling met deze certificering, die digitalisering en duurzaamheid binnen de productie bevordert. Het omarmen van deze strategieën zal niet alleen de vaardigheidskloof dichten, maar ook productiebedrijven positioneren voor duurzame groei en concurrentievermogen op de wereldmarkt.

Veelgestelde vragen over bijscholing en omscholing in de productie

Wat zijn de 4 strategieën voor bij- en omscholing?

De vier belangrijkste strategieën voor het bijscholen en omscholen van werknemers in de productie zijn:

- Opleiding op de werkplek

- Digitale leerplatformen

- Partnerschappen tussen de industrie en de academische wereld

- Certificeringsprogramma's

Deze benaderingen helpen werknemers nieuwe vaardigheden te verwerven voor slimme productie en Industrie 4.0.

Waarom is bijscholing belangrijk in de productie?

Bijscholing is belangrijk in de maakindustrie omdat het werknemers helpt zich aan te passen aan nieuwe technologieën, hun productiviteit te verbeteren en concurrerend te blijven in een snel veranderende Industrie 4.0-omgeving.

Wat is het verschil tussen bijscholing en omscholing in de productie?

Upskilling betekent het leren van nieuwe vaardigheden om te groeien in een huidige functie, terwijl reskilling het opleiden van werknemers voor volledig nieuwe functies inhoudt. Beide zijn essentieel in de productiesector om digitale transformatie en automatisering te ondersteunen.

Hoe kunnen fabrikanten een personeelsbestand creëren dat klaar is voor de toekomst?

Fabrikanten kunnen een toekomstbestendig personeelsbestand creëren door te investeren in continue training, digitale hulpmiddelen te omarmen, een leercultuur te creëren en de ontwikkeling van het personeel af te stemmen op de technologieën van Industrie 4.0.

Met welke uitdagingen worden fabrikanten geconfronteerd bij het opleiden van hun personeel?

Fabrikanten worden geconfronteerd met uitdagingen zoals beperkte opleidingsbudgetten, gebrek aan digitale geletterdheid, een vergrijzende beroepsbevolking en moeite om gelijke tred te houden met de snel veranderende technologieën op het gebied van slimme productie.

Wat zijn voorbeelden van bijscholing in slimme productie?

Voorbeelden van het bijscholen op het gebied van slimme productie zijn het opleiden van werknemers in het gebruik van robotica, data-analysetools, digitale tweelingen, IoT-platformen en op AI gebaseerde productiesystemen.

Welke invloed heeft Industrie 4.0 op personeelsplanning?

Industrie 4.0 heeft invloed op de personeelsbezetting door de vraag te verleggen naar technisch onderlegde functies, waardoor er nieuwe vaardigheden nodig zijn en fabrikanten gedwongen worden hun strategieën voor training, werving en behoud van talent te herzien.

Wat zijn de beste werkwijzen voor personeelstransformatie in de productiesector?

Aanbevolen werkwijzen voor de transformatie van de beroepsbevolking zijn onder andere het beoordelen van vaardigheidskloofjes, gepersonaliseerde leerpaden, leiderschapsontwikkeling, partnerschappen met leveranciers van technologie en het volgen van prestaties in lijn met de doelstellingen van Industrie 4.0.