Sa mabilis na takbo ng pagmamanupaktura ngayon, aktibong binabago ng mga pinuno ang kanilang mga operasyon gamit ang mga makabagong inobasyon, walang putol na pagsasama ng sustainability at teknolohiya na naaayon sa Industry 4.0. May kapangyarihan na ngayon ang mga tagagawa na baguhin ang kanilang matalinong proseso ng pagmamanupaktura gamit ang mga makabagong solusyon sa cleantech.

Gumagamit sila hydrogen upang palakasin ang kanilang mga operasyon, a roboctopus upang mahawakan ang mga maselang bagay tulad ng prutas at gulay, at lumipat sa eco-friendly na packaging tulad ng nabubulok na mga kahon ng fungi—ito ay ilan lamang sa mga halimbawa kung paano muling hinuhubog ng cleantech ang industriya.

Smart manufacturing is not just about adopting cleantech; it is driving rapid integration, providing businesses with significant competitive advantages. This rapid adoption of Environmental, Social, and Governance (ESG) friendly solutions has increased investment in the cleantech market.

Ayon sa Commodity Insights ng S&P Global, ang pandaigdigang taunang pamumuhunan sa cleantech ay inaasahang lalampas US$900 bilyon pagsapit ng 2030, halos triple ang paggasta mula 2020.

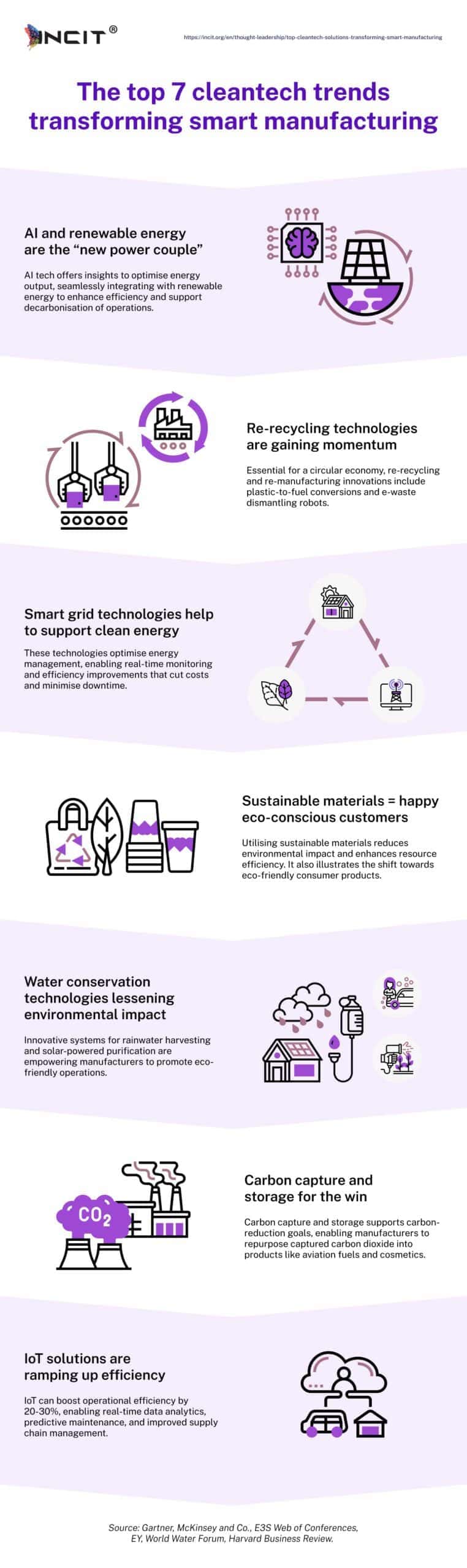

Ang sektor ng pagmamanupaktura ay gumaganap ng isang mahalagang papel sa paglago na ito, na nag-aambag sa paligid 0.7 per cent to the segment’s expansion. With spending by manufacturers on the rise, seven key cleantech trends have emerged, setting the stage for impactful transformation:

Pag-maximize sa mga benepisyo ng mga solusyon sa cleantech sa matalinong pagmamanupaktura

Sinusuportahan ng mga inobasyon ng Cleantech ang matalinong pagmamanupaktura sa iba't ibang paraan, na tinitiyak na ang mga manufacturer ay may kumpiyansa na mamumuhunan sa mga teknolohiyang cleantech na parehong makakalikasan at matipid. Mula sa napapanatiling produksyon ng pagkain hanggang sa mga biodegradable na plastik, hindi lamang nakikinabang ang cleantech sa kalusugan ng ESG ng mga negosyo ngunit pinahuhusay din nito ang kita.

Sa pamamagitan ng paggamit ng cleantech, maaaring itaguyod ng mga tagagawa ang napapanatiling pag-unlad, pagsasama-sama ng integridad ng kapaligiran sa paglago ng ekonomiya at nagbibigay daan para sa isang mas napapanatiling hinaharap. Sa pagbabagong kapangyarihan ng cleantech, ang industriya ng pagmamanupaktura ay nakahanda para sa isang mas luntian at mas maunlad na panahon.

Inendorso ng World Economic Forum (WEF), ang Consumer Sustainability Industry Readiness Index (COSIRI) gumaganap bilang isang komprehensibong balangkas ng ESG, na nagpapahusay sa pagpapanatili at kakayahang makita ang pag-unlad ng ESG sa buong sektor ng pagmamanupaktura. Ang matibay na tool na ito ay nagbibigay ng kapangyarihan sa mga tagagawa na pamahalaan ang mga pangunahing salik sa panganib nang mas epektibo, na nagbibigay ng isang madiskarteng kalamangan at nagpapaunlad ng pangmatagalang paglago.

Frequently Asked Questions About Cleantech Solutions Transforming Smart Manufacturing

What is Cleantech in Smart Manufacturing?

Cleantech in smart manufacturing refers to technologies that reduce environmental impact, enhance energy efficiency, and promote sustainable production practices. It includes innovations like renewable energy, energy management systems, and waste reduction technologies.

How Do Cleantech Solutions Support Sustainable Manufacturing?

Cleantech solutions support sustainable manufacturing by lowering carbon emissions, optimising resource use, reducing waste, and improving energy efficiency throughout the production process.

What Are the Top Cleantech Solutions Used in Smart Factories?

Top cleantech solutions in smart factories include solar power, energy-efficient robotics, AI-powered energy management, water recycling systems, and circular economy technologies that reuse materials.

Why is Cleantech Important for Smart Manufacturing?

Cleantech is crucial for smart manufacturing because it enables the achievement of sustainability goals, reduces operational costs, supports ESG compliance, and enhances factory efficiency and environmental responsibility.

What Industries Are Adopting Cleantech for Manufacturing?

Industries adopting cleantech include electronics, automotive, food processing, textiles, and heavy industry, especially those looking to lower emissions and improve energy performance.

How Does AI Improve Cleantech Applications in Manufacturing?

AI improves cleantech in manufacturing by enabling predictive maintenance, optimising energy usage, monitoring emissions, and making real-time decisions that reduce waste and increase efficiency.

What Are the Benefits of Using Cleantech in Industry 4.0?

Benefits include reduced environmental impact, improved compliance with green regulations, cost savings, better resource efficiency, and enhanced competitiveness in a sustainability-focused economy.

How is the Development of Cleantech Solutions Advancing Smart Manufacturing?

The development of cleantech solutions is advancing smart manufacturing by introducing cleaner production methods, energy-efficient systems, and digital tools that reduce environmental impact and support sustainable growth.

What Are Some Examples of Clean Technology in Manufacturing?

Examples of clean technology in manufacturing include solar-powered machinery, energy recovery systems, closed-loop water treatment, biodegradable materials, and AI-based emissions monitoring platforms.