The Deloitte'un araştırmasının da ortaya koyduğu gibi, üretimdeki önemli beceri açığı büyümeye devam ediyor. Araştırmaya göre, 2,1 milyon boş iş, ABD'ye yaklaşık $1 trilyonluk bir maliyete yol açacak. 2030 yılında tek başına. Mevcut ve gelecekteki yetenek eksikliğinin çeşitli nedenleri olduğunu biliyoruz, bunlar çoğunlukla yaşlanan iş gücünden, beceri setlerinin yetişemediği teknolojik gelişmelerden ve üretimde bir rolün nasıl olması gerektiğine dair modası geçmiş bir görüşten kaynaklanmaktadır tasvir edilen tehlikeli, gösterişsiz çalışma koşullarını anımsatıyor Amerikalı romancı Upton Sinclair'in "Orman" adlı romanı.

Buna göre ABD Ticaret Odası, Üretim sektöründeki iş ilanlarının yüzde 45'i henüz doldurulamadı. Dünya Ekonomik Forumu'nun 2023 İşlerin Geleceği Rapor, ileri üretimdeki mevcut beceri gereksinimlerinin 40'ının önümüzdeki beş yıl içinde evrim geçirmesinin beklendiğini vurguluyor. Liderler, bir ankete göre alarma geçti Ulusal Üreticiler Birliği (NAM)Üretim yöneticilerinin yaklaşık yüzde 75'i, birincil iş zorluklarının vasıflı işgücü eksikliği olduğunu belirtti.

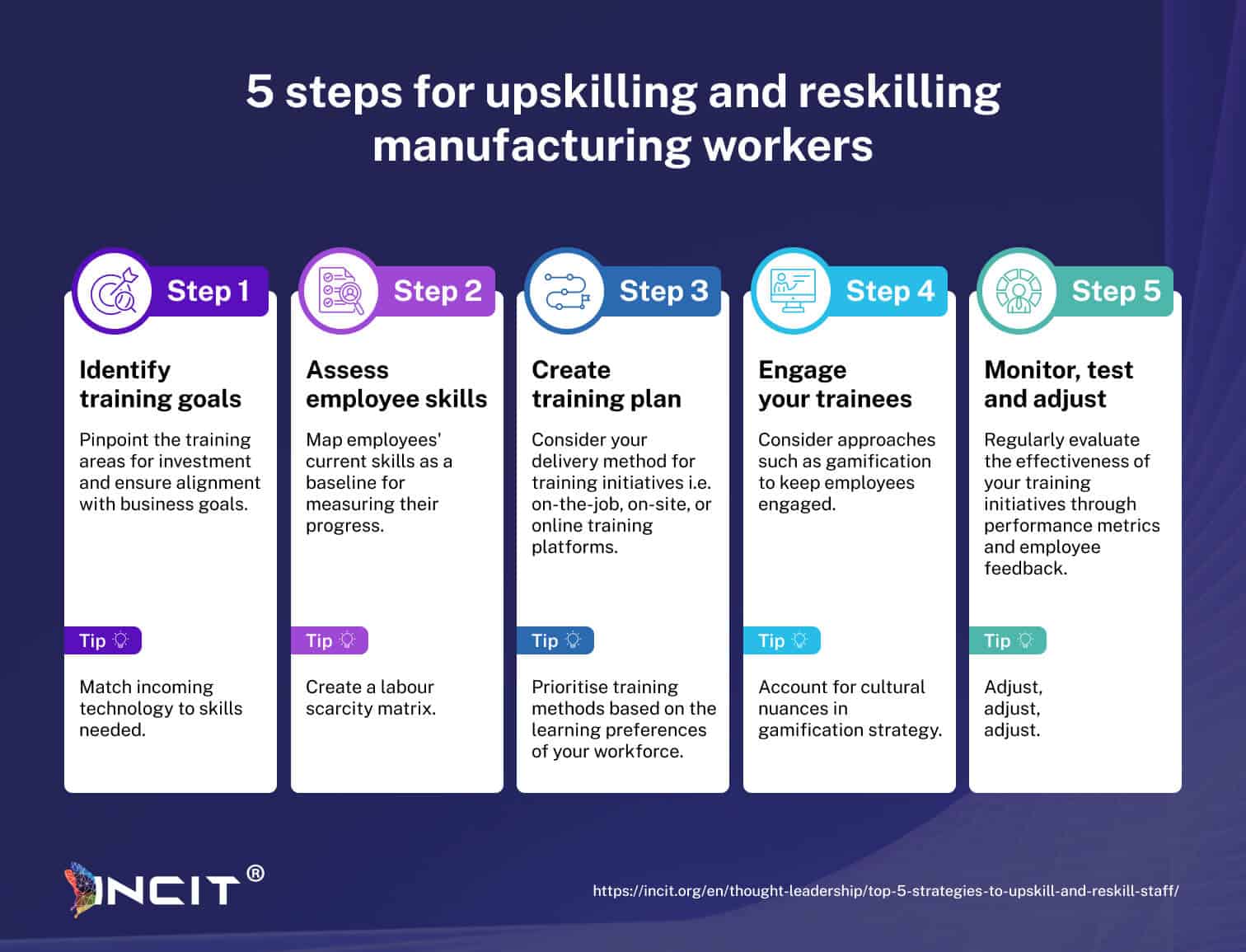

Üreticiler acil ilgi gerektiren önemli bir işgücü açığıyla boğuşuyor, ancak işletmeler yaklaşan yetenek krizine hazırlanmak için ne yapabilir? Aşağıda, hedeflenen beceri geliştirme programları aracılığıyla çalışanları güçlendirmek, işgücü zorlukları karşısında dayanıklılık ve büyümeyi sağlamak için atılması gereken temel adımları inceliyoruz.

Stratejik beceri geliştirme girişimleri yoluyla geleceğe hazır iş gücünü teşvik etmek

Üretim sektöründeki işgücü kıtlığı artık salgın haline geldi ve daha da kötüleşmesi bekleniyor. Üretim şirketlerinin beceri geliştirme ve yeniden beceri kazandırma girişimlerine yatırım yapması zorunludur. Gelişen iş rolleriyle uyumlu hedefli eğitim programları uygulayarak ve oyunlaştırma (yeniden beceri kazandırmayı daha ilgi çekici hale getirmek için kullanın!) gibi yenilikçi yöntemlerden yararlanarak, üreticiler işgücünü uyum sağlamaları için güçlendirebilir ve böylece işletmedeki işgücü açığını giderebilirler. Bu stratejileri benimsemek yalnızca beceri açığını kapatmakla kalmayacak, aynı zamanda üretim şirketlerini küresel pazarda sürdürülebilir büyüme ve rekabet gücü için konumlandıracaktır.

Ayrıca, aşağıdakiler gibi uzmanlaşmış eğitim programları: SIR/COSIRI Program tarafından sunulan İNTİKAM, üretimde dijitalleşme ve sürdürülebilirlik uygulamalarını ilerleten bu sertifika ile liderlerin devam eden beceri geliştirmelerine destek olabilir. Bu stratejileri benimsemek yalnızca beceri açığını kapatmakla kalmayacak, aynı zamanda üretim firmalarını küresel pazarda sürdürülebilir büyüme ve rekabet gücü için konumlandıracaktır.

Üretimde Yükseltme ve Yeniden Beceri Kazandırma Hakkında Sıkça Sorulan Sorular

Yeni Beceriler Kazandırmak ve Yeniden Beceri Kazandırmak İçin 4 Strateji Nelerdir?

Üretimde beceri geliştirme ve yeniden beceri kazandırmaya yönelik dört temel strateji şunlardır:

- İş başında eğitim

- Dijital öğrenme platformları

- Sanayi-akademi ortaklıkları

- Sertifika programları

Bu yaklaşımlar, çalışanların akıllı üretim ve Endüstri 4.0 için yeni beceriler kazanmasına yardımcı oluyor.

Üretimde Beceri Geliştirme Neden Önemlidir?

Üretimde becerilerin artırılması önemlidir çünkü çalışanların yeni teknolojilere uyum sağlamasına, üretkenliği artırmasına ve hızla değişen Endüstri 4.0 ortamında rekabetçi kalmasına yardımcı olur.

Üretimde Yeni Beceri Kazandırma ve Beceri Geliştirme Arasındaki Fark Nedir?

Beceri geliştirme, mevcut bir rolde büyümek için yeni beceriler öğrenmek anlamına gelirken, yeniden beceri geliştirme, çalışanları tamamen yeni roller için eğitmeyi içerir. Her ikisi de dijital dönüşümü ve otomasyonu desteklemek için üretimde olmazsa olmazdır.

Üreticiler Geleceğe Hazır Bir İş Gücünü Nasıl Yaratabilir?

Üreticiler, sürekli eğitime yatırım yaparak, dijital araçları benimseyerek, öğrenme kültürleri oluşturarak ve iş gücü gelişimini Endüstri 4.0 teknolojileriyle uyumlu hale getirerek geleceğe hazır bir iş gücü yaratabilirler.

Üreticiler İşgücü Eğitiminde Hangi Zorluklarla Karşılaşıyor?

Üreticiler, sınırlı eğitim bütçeleri, dijital okuryazarlığın eksikliği, yaşlanan iş gücü ve akıllı üretimde hızla değişen teknolojilere ayak uydurma zorluğu gibi zorluklarla karşı karşıya kalıyor.

Akıllı Üretimde Beceri Geliştirme Örnekleri Nelerdir?

Akıllı üretimde beceri geliştirme örnekleri arasında çalışanlara robotik, veri analitiği araçları, dijital ikizler, IoT platformları ve yapay zeka tabanlı üretim sistemlerini kullanma eğitimi verilmesi yer alıyor.

Endüstri 4.0 İşgücü Planlamasını Nasıl Etkiliyor?

Endüstri 4.0, talebi teknoloji meraklısı rollere kaydırarak, yeni beceriler gerektirerek ve üreticileri eğitim, işe alım ve yetenek elde tutma stratejilerini yeniden düşünmeye iterek işgücü planlamasını etkiliyor.

Üretimde İşgücü Dönüşümü İçin En İyi Uygulamalar Nelerdir?

İşgücü dönüşümüne yönelik en iyi uygulamalar arasında beceri açığı değerlendirmeleri, kişiselleştirilmiş öğrenme yolları, liderlik geliştirme, teknoloji sağlayıcılarıyla ortaklıklar ve Endüstri 4.0 hedeflerine bağlı performans takibi yer alıyor.