In today’s fast-evolving process manufacturing landscape, efficiency isn’t just an advantage; it’s a survival strategy. Across the chemical and pharmaceutical sectors, rising energy prices, variable raw-material quality, and increasing process complexity are testing even the most experienced engineers. As a result, plants lose millions each year, troubleshooting avoidable inefficiencies and chasing yield losses that could have been prevented. The problem lies in how optimisation has traditionally been done reactively, after performance drops, rather than proactively, before inefficiencies arise.

At Aleph Technologies, we believe the future of manufacturing lies in turning process data into foresight. Through advanced virtual simulation models and proprietary AI, Aleph recreates real manufacturing environments in a digital space, mirroring every reaction, unit operation, and material flow. Inside this environment, our AI runs thousands of “what-if” scenarios to explore how small changes in temperature, pressure, or feed flow could improve performance.

This simulation-driven approach empowers engineers to uncover the most energy-efficient and high-yield operating conditions before making any real-world adjustments. The result is measurable reductions in energy costs, improved product consistency, and fewer unplanned disruptions.

Join Suwira Teo and Dr. Sushant Garud, Co-Founders of Aleph Technologies, as they explain how manufacturers are using simulation-driven AI to move from reactive troubleshooting to proactive optimisation—achieving tangible gains in performance, reliability, and profitability.

What to Expect from This Webinar

This session will provide valuable insights on:

- Why conventional optimisation limits plant performance, and how simulation-driven AI changes that dynamic.

- How virtual models predict the most energy-efficient and high-yield operating conditions.

- How real-world plants have reduced costs, improved output quality, and enhanced decision-making accuracy.

- Practical steps to bring simulation-driven AI into your facility.

Why Attend?

- Shift from reactive problem-solving to proactive, data-driven optimisation. Learn how AI and simulation models can help identify performance risks before they affect yield or energy use.

- Discover how to combine physical process simulation with AI-driven insights to achieve predictive optimisation in process manufacturing.

- Gain hands-on understanding of how Aleph Omega™ enables virtual testing of thousands of “what-if” scenarios to determine optimal operating conditions without disrupting live production.

- Explore how predictive analytics can enhance decision-making, improve energy efficiency, and stabilise production performance.

- Connect with Aleph Technologies’ experts and learn how to apply AI as a decision-support tool in your operations.

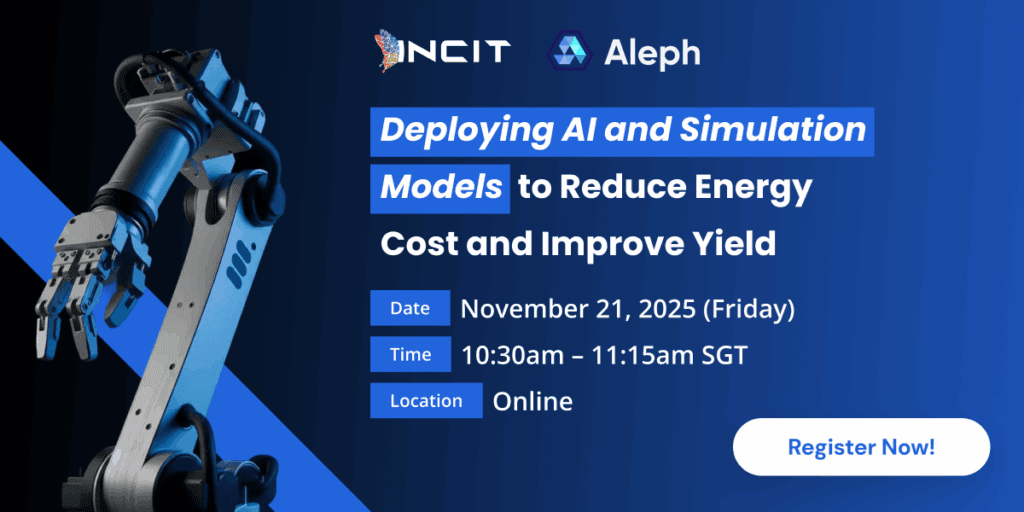

Webinar Details:

- Date: November 21, 2025 (Friday)

- Time: 10:30am – 11:15am SGT

- Location: Online

- Register here: http://tinyurl.com/incitxaleph

Register Now

Process manufacturing is highly sensitive to variability: Small changes in feed quality, conditions, or equipment can cause major efficiency and yield losses. This session is designed for INCIT-Certified Assessors, process engineers, plant managers, manufacturing leaders, and digital transformation professionals seeking to move from reactive troubleshooting to predictive optimisation.

Consultants, system integrators, and technology leaders will gain insight into how simulation-driven AI can integrate with existing systems to deliver data-backed performance improvements, while operational excellence teams and solution providers will see how predictive models enhance decision-making and drive consistent, measurable results.

By attending, you’ll discover how simulation and AI act as a process co-pilot—helping you anticipate problems, optimise setpoints, and operate more efficiently and reliably.

About Aleph Technologies

Aleph Technologies is a Singapore-based AI company helping process manufacturers optimise complex operations through its Aleph Omega™ platform. By combining AI, virtual simulation models, and domain expertise in chemistry and thermodynamics, Aleph enables manufacturers to identify performance gaps, simulate optimal conditions, and make real-time decisions that deliver greater efficiency, reliability, and profitability.

For more details and updates, follow our announcement on LinkedIn here

For collaboration & further enquiries, please contact contact@incit.org or Ask IC4IT