レッドオーシャンを生き抜く:中小製造企業のための実践的ロードマップ

中小製造業者の厳しい現実 中小製造業者は常に厳しい状況に置かれてきました。しかし、競争が熾烈で、利益率が低く、ルールが常に変化し続ける今日のレッドオーシャン市場では、生き残ることさえ成功のように感じられるようになっています。膨大なリソースと規模の経済性を活用する大手多国籍企業(MNC)が支配するこの熾烈な競争環境は、中小製造業者を不安定な立場に追い込んでいます。残念ながら、生き残るだけでは十分ではありません。これらの企業が生き残り、未来を築くためには、彼らの仕事のやり方、つまりペースが速く、リソースが限られており、デジタル変革の課題では見過ごされがちなやり方に適した構造とツールが必要です。その可能性は極めて低いです。米国だけでも、[…]

スキル・ケララ・グローバルサミット2025:仕事と人材の未来を形作る

2025年8月29日~30日、コーチはスキル・ケララ・グローバル・サミット2025を開催し、スキル、イノベーション、そして仕事の未来に関する世界的な対話の中心地となりました。この画期的なイベントには、思想的リーダー、業界のパイオニア、政策立案者、学者、起業家、そして変革を目指す人々が集まり、共通の目標、すなわちケララ州を世界の人材育成における最高の目的地として確固たる地位に押し上げるという目標を掲げました。サミットでは、世界中の産業界におけるスキルニーズの進化に焦点を当てるとともに、ケララ州が人材、イノベーション、そして起業家精神の活気ある拠点となる可能性を示しました。教育、産業、そして雇用を繋ぐこのサミットは、変革をもたらす成長と世界的な連携を促進する触媒となりました。変革のためのプラットフォーム スキル・ケララ […]

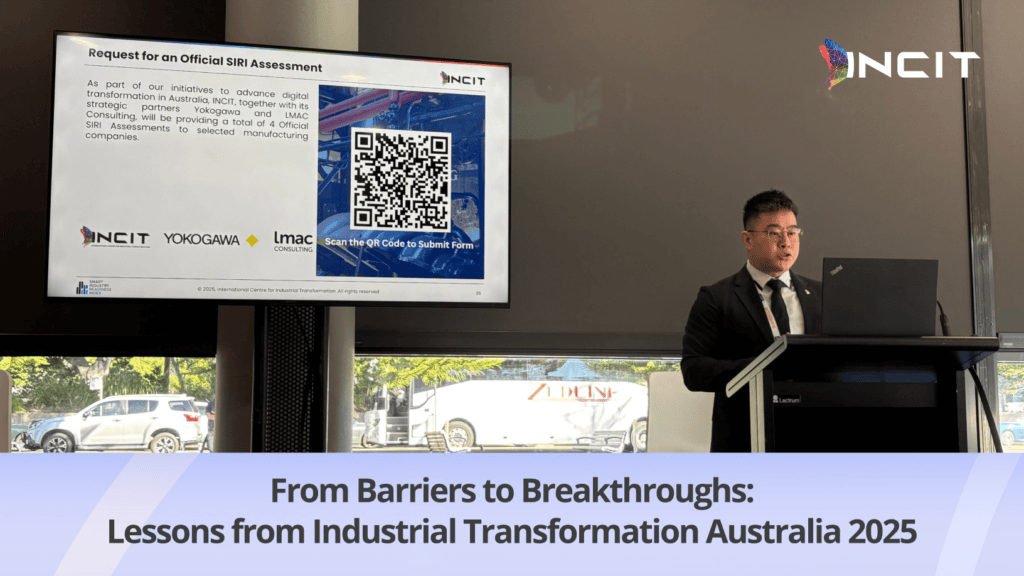

障壁の除去:オーストラリア産業変革2025の概要

オーストラリアにおける産業変革 - 障壁の除去フォーラムは、2025年7月23日、シドニー・オリンピック・パークにて、産業変革オーストラリア(ITA)2025の一環として開催されました。インダストリー・ケイパビリティ・ネットワーク(ICN)が主催し、SeerPharmaと国際産業変革センター(INCIT)のソートリーダーシップ・プログラム「グローバル・エグゼクティブ・インダストリー・トークス(GETIT)」の支援を受けたこのイベントでは、業界リーダー、政策立案者、イノベーターが一堂に会し、オーストラリアの製造業を形作る喫緊の課題と機会について議論しました。ターゲットを絞ったフォーラムとして企画されたこのセッションでは、デジタル変革の障壁を取り除き、組織がインダストリーX.0への取り組みを開始、拡大、そして維持するための戦略を策定することに焦点を当てました。議論は、規制上の考慮事項、[…]

共に変革する:CII年次ビジネスサミット2025におけるINCIT

インド産業連盟(CII)が主催する2025年年次ビジネスサミットは、「信頼の構築 ― インド第一主義」をテーマとし、2日間にわたり2,500人の代表者、134人の講演者、そして12人の大臣が参加し、活発なハイレベル対話が行われました。2つの会場で35のセッションが開催されたサミットは、急速に変化する世界情勢におけるインドの経済的役割の進化を探る重要なプラットフォームとなりました。国際産業変革センター(INCIT)を代表して、CEOのライムンド・クライン氏は、2025年5月30日に開催されたセッション「学習から収入へ:雇用格差の解消」に登壇しました。クライン氏の参加は、議論に貴重な視点をもたらし、産業界、教育、政策がどのように連携して雇用格差の解消に取り組むことができるかについて、より幅広い議論に貢献しました。[…]

チームのデジタルリテラシーを評価することがイノベーションを解き放つ鍵となる理由

製造業は、デジタル変革を推進するために、重要な課題を抱えています。その一環として、強力なデジタルリテラシー文化と能力の育成、そして各事業に特有のデジタル能力の開発が挙げられます。しかし、その重要性にもかかわらず、デジタルリテラシーはビジネスにおいて依然として曖昧な用語であり、多くのリーダーが依然として苦戦している分野です。しかし、より強力なデジタルリテラシーとデジタルスキル能力の開発は、スマート製造業の潜在能力を解き放つ鍵となります。リーダーは、将来の成長とイノベーションを促進するために、現在のデジタルスキルレベルを評価・測定し、強化すべきギャップを特定することを優先する必要があります。ラブ・スコット教授は[…]

INCITと横河電機中東アフリカが戦略的パートナーシップを締結し、湾岸地域の産業変革を推進

シンガポール – 2025年6月18日 – 国際産業変革センター(INCIT)と横河電機ミドルイースト・アフリカは、サウジアラビア王国、バーレーン王国、オマーン国におけるデジタル変革イニシアチブを推進するための戦略的提携契約を締結したことを発表いたします。このパートナーシップは、製造業企業のオペレーショナル・エクセレンスとデジタル成熟度を評価・向上させることで、第四次産業革命時代に向けた地域の産業変革を加速させることを目的としています。INCITの世界的に認められているスマートインダストリー準備指標(SIRI)と、最近発表されたオペレーショナル・エクセレンス準備指標(OPERI)を活用することで、企業は自社の現在の能力をより深く理解し、 […]

貴社の製造部門はインダストリー X.0 への対応準備ができていますか、それともただ話しているだけですか?

ますます不安定化する世界情勢の中、製造業は重大な岐路に立たされています。パンデミック、気候変動、地政学的緊張、そして加速する技術革新によって引き起こされた混乱は、脆弱性を露呈させただけでなく、変革の緊急性を浮き彫りにしました。レジリエンス(回復力)と長期的な競争力の構築を目指す製造業にとって、デジタル化はもはや戦略的な選択肢ではなく、必須事項となっています。この複雑な環境を乗り越えるべく、業界のステークホルダーの皆様を支援するため、最新のホワイトペーパー「グローバル・スマート・インダストリー・レディネス・インデックス(SIRI)イニシアチブ:製造業変革インサイト・レポート2025」を公開いたします。このレポートは、60カ国以上にわたる数千の製造企業からのデータに基づく洞察を提供し、グローバルな[…]

グローバルスマートインダストリー準備指数(SIRI)イニシアチブ:製造業変革インサイトレポート2025

サプライチェーンの混乱、気候変動対策、急速な技術革新など、製造業は世界的なプレッシャーの高まりに直面しており、変革はもはや選択肢ではありません。このホワイトペーパーでは、60カ国以上の数千社の製造企業から得られた知見を紹介し、業界を形作る主要なトレンドと、戦略ビジョンと業務遂行の間に存在する重大なギャップを明らかにしています。スマートインダストリー準備指数(SIRI)ホワイトペーパー2025 スマートインダストリー準備指数(SIRI)などのフレームワークが、製造業がこのギャップを埋め、レジリエンスを構築し、デジタルトランスフォーメーションを通じて持続可能な成長を促進する上でどのように役立っているかをご覧ください。

製造業におけるデジタル変革プロジェクトが失敗する主な3つの理由(およびその回避方法)

デジタルトランスフォーメーション(DX)は目的地ではなく、旅路です。製造業とそのリーダーは、主要なデジタルイニシアチブを実行するだけでなく、その過程において最適化を行うための適切な戦略と人材を確保する必要があります。インターナショナル・データ・コーポレーション(IDC)は、製造業におけるDX支出額が今年、世界全体で1兆5,816億ドルを超えると予測しています。インダストリー4.0への移行は、製造業の経営者にとって重要な優先事項であり、その重要性は増しています。なぜなら、事業の存続そのものが主要なデジタルイニシアチブの成功にかかっているからです。製造業の経営者は、この取り組みに緊迫感を強めています[…]

デジタルトランスフォーメーションとは何か、そして2025年になぜ重要なのか

はじめに デジタルトランスフォーメーションとは何か、そしてなぜそれが重要なのか、疑問に思ったことはありませんか?急速な技術革新が進む世界において、デジタルトランスフォーメーションはもはや流行語ではなく、ビジネスに不可欠な要素となっています。2025年を迎えるにあたり、あらゆる業界の組織が、価値の提供方法、顧客エンゲージメント、そして将来を見据えた事業運営のあり方を見直しています。しかし、今日のデジタルトランスフォーメーションとは一体何を意味するのでしょうか?どのように進化してきたのでしょうか?そして何よりも重要なのは、なぜ今、あなたの組織にとって重要なのでしょうか?この記事では、2025年のデジタルトランスフォーメーションの定義、主要な推進要因、新たなトレンド、そしてビジネスへの影響を探ります。中小企業、政府機関、多国籍企業など、あらゆる立場の方に、本書の内容はきっとお役に立てるはずです。[…]

能力フレームワークとは何ですか? なぜそれが重要なのですか?

はじめに 今日の急速に変化するテクノロジー主導の世界では、産業界は、常に時代のニーズに応え、レジリエンス(回復力)と責任感を持ち続けることが求められています。組織が進化するにつれ、人材とプロセスの定義、評価、育成の方法も進化させる必要があります。ここで、ケイパビリティ・フレームワークが重要な役割を果たします。ケイパビリティ・フレームワークは単なる流行語ではありません。戦略目標を達成するために必要な知識、スキル、行動を理解し、育成するための体系的なアプローチです。多国籍メーカーであれ、公共機関であれ、適切に設計されたケイパビリティ・フレームワークを導入することは、デジタル変革の礎となり得ます。この記事では、ケイパビリティ・フレームワークとは何か、なぜ重要なのか、そして組織がそれをどのように活用して、潜在能力を解き放つことができるのかを探ります。[…]

INCITとDeteconが提携し、産業AIの変革を推進

シンガポールおよびケルン、2025年2月28日 – 国際産業変革センター(INCIT)とDeteconは、産業AIへの変革を加速させるための戦略的パートナーシップを発表しました。この提携により、INCITとDeteconは、製造業におけるAI成熟度を評価するための包括的な優先順位付け指標である「産業人工知能準備指数(AIRI)」を発表します。INCITの産業評価に関する専門知識と、Deteconのデジタル化、AI、データ駆動型製造に関する深い知識を活用することで、企業はAI能力に関する洞察を得て、AI導入に向けた戦略的ガイダンスを得ることができます。DeteconはAI評価手法の開発に貢献しており、[…]

共に強くなる – 人間と人工知能は協力して業務の卓越性を実現します

世界経済フォーラムによると、米国の労働者の約5人に1人が、AIによって自分たちが時代遅れになるのではないかと懸念しています。この不安は「FOBO(陳腐化への恐怖)」と呼ばれ、私たちが生み出すイノベーションやテクノロジーによって人間が不要になるという懸念を意味します。しかし、賢明な製造業のリーダーたちは、AIが業務に応用され、特に人間の知能と組み合わせることで、変革をもたらす力を持っていることを認識しています。製造業のリーダーたちは、現代の課題に対応するため、リーン生産方式、品質管理、サプライチェーンの最適化を通じて、オペレーションの卓越性(OPEX)の追求を優先していますが、AIほどこの分野での進歩を促進するツールはほとんどありません。[…]

INCITがカタールのデジタル変革とインダストリー4.0に関する対話に参加

財務省は先日、カタール開発銀行(QDB)と共同で、デジタルトランスフォーメーションとインダストリー4.0に焦点を当てた重要なイベントをカタールで開催しました。このイベントには、世界中から業界の専門家、思想的リーダー、意思決定者が集まり、カタールの産業と商業の将来について議論しました。INCITはこのイベントに参加し、カタールの産業と技術の成長を促進するための継続的な対話と取り組みに貢献できたことを誇りに思います。戦略的パートナーシップによるイノベーションの促進 INCITの最高執行責任者であるジェスモンド・ホン博士は、「グローバルテクノロジートレンドと先進製造業」に関するディスカッションにパネリストとして参加しました。他の業界専門家と共に、ホン博士は最新の技術に関する知見を共有しました。[…]

スマート産業準備指数によるエジプトの製造業の変革

エジプトの製造業の未来は、スマートインダストリー準備指数(Smart Industry Readiness Index)の導入により、変革的な飛躍を遂げようとしています。あらゆる規模と業種の製造業者を支援するために開発されたSmart Industry Readiness Indexは、企業がデジタルトランスフォーメーションの取り組みを開始、拡大、そして継続できるよう支援することを目的としています。この先駆的な取り組みは、国際産業変革センター(INCIT)、産業近代化センター(IMC)、情報技術産業開発庁(ITIDA)、ドイツ国際協力機構(GIZ)の協力によって実現しました。スマートインダストリー準備指数:インダストリー4.0のためのフレームワーク スマートインダストリー準備指数は、製造業者に実用的なツールを提供する世界的に認められたフレームワークです。[…]

インダストリー4.0時代の持続可能な製造業におけるデータのプライバシーとセキュリティ

インダストリー4.0は2011年に誕生したことが広く知られていますが、10年以上が経過した今、製造業はまさにデータ主導の革命の真っ只中にあります。世界経済フォーラムのホワイトペーパーによると、インダストリー4.0は、企業が相互接続されたバリューネットワークに力を合わせ、データと分析アプリケーションを活用することで生産性の向上、新たな顧客体験の創出、そして社会と環境への大きなインパクトを生み出すことを促すとされています。デロイト コンサルティングのグローバル インダストリーおよびシニア クライアント アドバイザーであるゲイリー・コールマン氏は、「第四次産業革命はまだ初期段階にある」と述べていますが、この時代がさらに進展するにつれて、これまでにないほど多くの可能性が解き放たれ続けるでしょう。

マイクロファクトリー:小規模で高度に自動化された工場が製造業の未来である理由

インダストリー4.0によるデジタル変革が製造業を取り巻く環境を大きく変えたことは疑いようがありません。人工知能(AI)や自動化といった技術により、製造業は業務効率を大幅に向上させ、生産性(最大15%から30%の増加)とダウンタイム(30%から50%の減少)の大幅な削減を実現しています。これらの技術革新は、マイクロファクトリーの普及にもつながっています。マイクロファクトリーとは、最先端のツールとソリューションを活用することで競争優位性を獲得し、従来の大規模工場では実現が難しい新たなレベルの柔軟性と拡張性を提供する小規模工場です。AI、機械学習、ビッグデータなどの革新的技術を活用することで、無駄の排除、プロセス […]

次世代製造工場のエンドツーエンドのデジタル変革を監督するための6つのステップ

世界中の製造施設の能力は飛躍的に向上し、組織は業務効率の向上、ステークホルダーとのリアルタイムな連携、部門間の連携強化を実現しています。そのため、イノベーションの限界を押し広げるため、自社の製造工場や施設にエンドツーエンドのデジタルアプローチを導入しようとする組織リーダーが増えています。しかし、熾烈な競争、環境意識の高まりを背景にした顧客の増加、そして常に変化する規制環境により、実現可能なデジタルトランスフォーメーションは容易ではありません。多くのデジタルトランスフォーメーション・プロジェクトにつきものの落とし穴を避けたいリーダーにとって、以下の6つのステップが役立ちます。1) 目標を明確にする 目標達成から始める。組織として、何を目標とするのかを理解し、合意することが重要です。[…]

デジタルトランスフォーメーションが繊維製造業の生産性をどのように向上させるか

繊維製品は日常生活に欠かせない存在です。衣類や家具から寝具、そして個人用保護具やサージカルマスクといった医療用繊維に至るまで、繊維製品なしでは生活を送ることはほぼ不可能です。サプライチェーンの問題やエネルギーコストの高騰といった問題に対処しながらこの需要に応えるため、繊維メーカーはより少ない資源でより多くのものを生み出すことで生産性を向上させる方法を模索してきました。そして、デジタルトランスフォーメーションがその鍵となるかもしれません。なぜデジタルトランスフォーメーションは繊維業界にとって重要なのでしょうか?近年、製造業における生産性危機は深刻化しており、特に繊維業界では顕著です。この背景には3つの大きな要因があります。まず、繊維サプライチェーン […]

製造業におけるデジタルトランスフォーメーションが現場のインテリジェンスを実現し、業務改善を実現する方法

手作業によるプロセスでは、製造部門と品質管理部門がサイロ化してしまうことがよくあります。これは、製造部門と品質管理部門のマネージャーが製品やプロセスを物理的に確認し、その結果をペンと紙で記録することが多いためです。この情報が組織の意思決定者に届くかどうかは不確実で、透明性の問題につながります。産業用IoT(IIoT)を活用することで、メーカーはデジタル製造現場を構築し、最初から現場インテリジェンスを確立することができます。適切なサポートがあれば、現場インテリジェンスは保証問題のリスクを軽減し、合理化・効率的なプロセスを構築し、無駄を削減することで、より高品質な製品と大幅なコスト削減を実現します。現場インテリジェンスの4つのメリット – そして、それらを施設に統合する方法 現場インテリジェンスには、主に4つのメリットがあります […]

2023年の見通し:製造業の成長に影響を与える3つのトレンド

世界がCOVID-19後の世界へと移行する中、製造業をはじめとする各業界は、世界的な不確実性が続く中で成長を目指し、プロセスの再調整を目指しています。サプライチェーンの問題が徐々に改善し、世界中でデジタル変革とビジネス変革が進む中、2023年には製造業の改善、成長、そして拡大を支援する機会が生まれるでしょう。特に、世界は中国のロックダウン解除を注視しています。ここでは、ビジネスリーダーが認識すべき2023年の製造業の3つのトレンドと、それらへの対応策をご紹介します。人材とスキル管理は依然として主要な懸念事項です。製造業の人材プールは縮小しています。2010年代後半にも、高齢化に関する警鐘が鳴らされていました[…]

スマートインダストリー準備指数に注目:製造業におけるデジタル変革を加速させるために組織と政府がいかに協力するか

多国間組織や政府は協力して、製造業者のデジタル変革の取り組みを支援することができます。