INCITとAIDSMOの戦略的提携によりアラブの産業変革を加速

アラブ産業変革を加速させるため、INCITとAIDSMOが戦略的パートナーシップを締結 国際産業変革センター(INCIT)は、アラブ産業開発・標準化・鉱業機構(AIDSMO)との協力協定を締結したことを発表いたします。この協定は、2025年9月30日、モロッコのベン・ゲリルにて、モハメッド6世工科大学(UM6P)主催の次世代製造業サミット「アフリカ」において調印されました。この協定は、INCIT CEOのライムンド・クライン氏とAIDMO事務局長補佐のタウフィク・アルルバイ氏によって正式に調印され、AIDSMO加盟国全体における包摂的かつ持続可能な産業発展を支援するという共通のコミットメントを示すものです。中小企業の支援とデジタル変革の実現 この戦略的提携は、中小零細企業のエンパワーメントに焦点を当てています。[…]

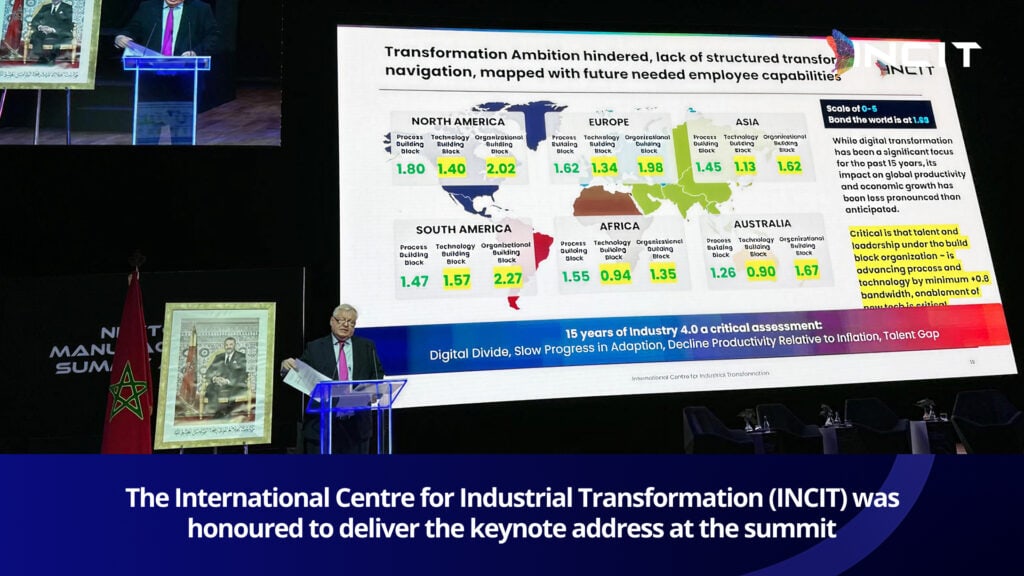

次世代製造業サミットアフリカ2025:アフリカ4.0:アフリカの製造業の未来を形作る

NextGen Manufacturing Summit Africa 2025:アフリカ4.0:アフリカ製造業の未来を形作る 先日開催されたNextGen Manufacturing Summit Africa 2025は、アフリカ大陸の産業の未来にとって決定的な瞬間となり、「アフリカ4.0」のビジョンを推進するために、アフリカ全土および世界中から主要な関係者が一堂に会しました。1,200名を超える参加者が会場に集まり、さらに1,000名がオンラインで参加したこのイベントは、イノベーション、持続可能性、そして協働を通してアフリカの製造業のあり方を変革しようとする、高まる勢いと共通の野心を示しました。国際産業変革センター(INCIT)は、このサミットで基調講演を行う栄誉に浴しました。CEOのライムンド・クライン氏は、アフリカがアフリカ4.0へと発展するために必要な戦略的道筋について、INCITの見解を共有しました。

INCIT は、INCIT シンガポールで 30 名を超えるトップビジネスリーダーからなるインド業界代表団の訪問を主催できることを光栄に思います。

INCITは、30名を超えるインドのトップビジネスリーダーからなるインド産業代表団をINCITシンガポールに迎えることができ、大変光栄に思います。国際産業変革センター(INCIT)は、グローバルな連携と産業革新の力強い証として、30名を超えるインドのトップビジネスリーダーからなる著名な代表団をシンガポールに迎えるという栄誉に浴しました。インドの大手製造企業の幹部で構成される代表団は、インド産業大臣を団長とし、インドの主要な業界団体であるFICCI、CII、ASSOCHAMの幹部も参加しました。今回の訪問は、インドとシンガポールの二国間産業関係の強化、そしてデジタルを活用したグローバルなグローバル経済発展という共通ビジョンの推進において、重要な節目となりました。

スキル・ケララ・グローバルサミット2025:仕事と人材の未来を形作る

2025年8月29日~30日、コーチはスキル・ケララ・グローバル・サミット2025を開催し、スキル、イノベーション、そして仕事の未来に関する世界的な対話の中心地となりました。この画期的なイベントには、思想的リーダー、業界のパイオニア、政策立案者、学者、起業家、そして変革を目指す人々が集まり、共通の目標、すなわちケララ州を世界の人材育成における最高の目的地として確固たる地位に押し上げるという目標を掲げました。サミットでは、世界中の産業界におけるスキルニーズの進化に焦点を当てるとともに、ケララ州が人材、イノベーション、そして起業家精神の活気ある拠点となる可能性を示しました。教育、産業、そして雇用を繋ぐこのサミットは、変革をもたらす成長と世界的な連携を促進する触媒となりました。変革のためのプラットフォーム スキル・ケララ […]

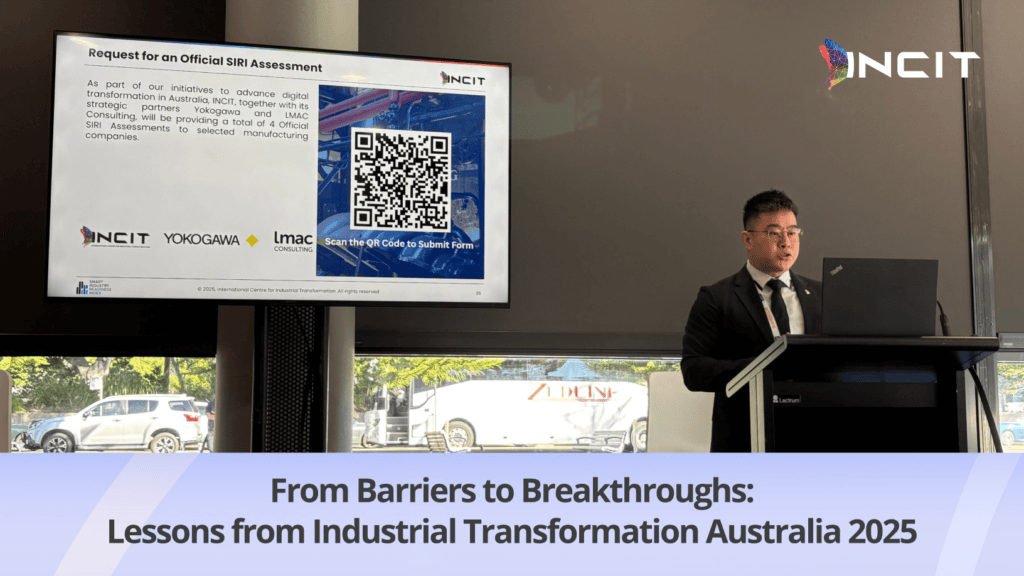

障壁の除去:オーストラリア産業変革2025の概要

オーストラリアにおける産業変革 - 障壁の除去フォーラムは、2025年7月23日、シドニー・オリンピック・パークにて、産業変革オーストラリア(ITA)2025の一環として開催されました。インダストリー・ケイパビリティ・ネットワーク(ICN)が主催し、SeerPharmaと国際産業変革センター(INCIT)のソートリーダーシップ・プログラム「グローバル・エグゼクティブ・インダストリー・トークス(GETIT)」の支援を受けたこのイベントでは、業界リーダー、政策立案者、イノベーターが一堂に会し、オーストラリアの製造業を形作る喫緊の課題と機会について議論しました。ターゲットを絞ったフォーラムとして企画されたこのセッションでは、デジタル変革の障壁を取り除き、組織がインダストリーX.0への取り組みを開始、拡大、そして維持するための戦略を策定することに焦点を当てました。議論は、規制上の考慮事項、[…]

複雑性から明確性へ:INCITがTÜV SÜD中国セミナーで意思決定主導の変革に関する洞察を共有

製造業者がデジタル化を急ぐ中、多くの企業が行き詰まりに陥っています。 – 30%の変革投資が効果を上げられていない – 43%のスマート生産ラインがサイバー脅威に対して脆弱なまま – 20%の意思決定がデータ品質の低さによって歪んでいる これらの差し迫った課題に対処するため、TÜV SÜD Chinaは2025年6月20日に「TÜV SÜDアカデミー:スマート製造変革の体系的導入に関するセミナー」を開催しました。「基盤としての標準、突破口としてのセキュリティ、データ主導のイノベーション」をテーマにしたこのセミナーでは、製造業者が陥りがちな落とし穴を回避し、大規模かつ確実に機能する変革戦略を構築するためのロードマップが提供されました。スマート製造における標準の役割 […]

INCITと横河電機中東アフリカが戦略的パートナーシップを締結し、湾岸地域の産業変革を推進

シンガポール – 2025年6月18日 – 国際産業変革センター(INCIT)と横河電機ミドルイースト・アフリカは、サウジアラビア王国、バーレーン王国、オマーン国におけるデジタル変革イニシアチブを推進するための戦略的提携契約を締結したことを発表いたします。このパートナーシップは、製造業企業のオペレーショナル・エクセレンスとデジタル成熟度を評価・向上させることで、第四次産業革命時代に向けた地域の産業変革を加速させることを目的としています。INCITの世界的に認められているスマートインダストリー準備指標(SIRI)と、最近発表されたオペレーショナル・エクセレンス準備指標(OPERI)を活用することで、企業は自社の現在の能力をより深く理解し、 […]

貴社の製造部門はインダストリー X.0 への対応準備ができていますか、それともただ話しているだけですか?

ますます不安定化する世界情勢の中、製造業は重大な岐路に立たされています。パンデミック、気候変動、地政学的緊張、そして加速する技術革新によって引き起こされた混乱は、脆弱性を露呈させただけでなく、変革の緊急性を浮き彫りにしました。レジリエンス(回復力)と長期的な競争力の構築を目指す製造業にとって、デジタル化はもはや戦略的な選択肢ではなく、必須事項となっています。この複雑な環境を乗り越えるべく、業界のステークホルダーの皆様を支援するため、最新のホワイトペーパー「グローバル・スマート・インダストリー・レディネス・インデックス(SIRI)イニシアチブ:製造業変革インサイト・レポート2025」を公開いたします。このレポートは、60カ国以上にわたる数千の製造企業からのデータに基づく洞察を提供し、グローバルな[…]

グローバルスマートインダストリー準備指数(SIRI)イニシアチブ:製造業変革インサイトレポート2025

サプライチェーンの混乱、気候変動対策、急速な技術革新など、製造業は世界的なプレッシャーの高まりに直面しており、変革はもはや選択肢ではありません。このホワイトペーパーでは、60カ国以上の数千社の製造企業から得られた知見を紹介し、業界を形作る主要なトレンドと、戦略ビジョンと業務遂行の間に存在する重大なギャップを明らかにしています。スマートインダストリー準備指数(SIRI)ホワイトペーパー2025 スマートインダストリー準備指数(SIRI)などのフレームワークが、製造業がこのギャップを埋め、レジリエンスを構築し、デジタルトランスフォーメーションを通じて持続可能な成長を促進する上でどのように役立っているかをご覧ください。

日立とINCIT、スマートインダストリー準備指標(SIRI)とXIRI-Analyticsを活用しデジタルトランスフォーメーションを推進すべく提携

シンガポール/日本、2025年3月26日 – 株式会社日立製作所(東証一部:6501、以下「日立」)とInternational Centre for Industrial Transformation Ltd.(以下「INCIT」)は本日、INCITと提携し、スマートインダストリー準備指標(SIRI)およびXIRI-Analyticsを導入することで、日立のグローバル製造業におけるデジタルトランスフォーメーションを加速します。日立は、次期中期経営計画において、デジタルを核とした「True One Hitachi」の実現と、社会イノベーション事業のさらなる成長を目指しています。こうした持続的な成長を実現するためには、IT、OT、プロダクトといった日立の強みを活かし、グローバルで独自の価値創造を加速していくことが不可欠です。そのためには、[…]

オマーン、主要覚書で産業の未来を築く、INCITがデジタル変革を推進

2025年2月9日に開催されたオマーン産業デーは、同国の産業成長と将来計画に焦点を当てたイベントです。商工投資促進省(MoCIIP)が主催する今年のテーマは、「グローバルサプライチェーンの中核を担うオマーン」であり、世界貿易と製造業における同国の役割を反映しています。イベントには、政府関係者、ビジネスリーダー、業界専門家が一堂に会し、オマーンの経済多様化と産業発展の進捗状況について議論が行われました。特に注目すべきは、オマーンの製造業が2024年に8兆5100億リアル(約1兆6000億円)成長し、26億8600万リアル(約26億8600万リアル)に達したことです。政府はまた、再生可能エネルギー、医療・食品産業、金属、建設資材など、主要分野にわたる100件の新規産業プロジェクト(総額15億リアル)を発表しました。これらの投資は、オマーンの[…]

スマート産業準備指数によるエジプトの製造業の変革

エジプトの製造業の未来は、スマートインダストリー準備指数(Smart Industry Readiness Index)の導入により、変革的な飛躍を遂げようとしています。あらゆる規模と業種の製造業者を支援するために開発されたSmart Industry Readiness Indexは、企業がデジタルトランスフォーメーションの取り組みを開始、拡大、そして継続できるよう支援することを目的としています。この先駆的な取り組みは、国際産業変革センター(INCIT)、産業近代化センター(IMC)、情報技術産業開発庁(ITIDA)、ドイツ国際協力機構(GIZ)の協力によって実現しました。スマートインダストリー準備指数:インダストリー4.0のためのフレームワーク スマートインダストリー準備指数は、製造業者に実用的なツールを提供する世界的に認められたフレームワークです。[…]

蘇州工業園区、インダストリー4.0の発展を加速させるスマート産業準備指数トレーニングを開催

[2024年9月] – 蘇州工業園区(SIP)は、INCITの研修・認証パートナーであるTÜV SÜD、およびボッシュ・エンパワーメント・センターと共同で、2024年9月にスマートインダストリー・レディネス・インデックス研修を開催しました。この取り組みは、企業のインダストリー4.0およびスマートマニュファクチャリングの目標達成を支援することを目的としています。主催者であるSIPは、中国とシンガポールの合弁企業であり、278平方キロメートルの敷地を有し、スマートマニュファクチャリング、バイオメディカル、ナノテクノロジーといったハイテク産業の推進に取り組んでいます。また、スマートインダストリー・レディネス・インデックス研修などの主要イベントも開催し、技術革新と業界リーダーシップの推進に貢献しています。SIPは、世界最先端のデジタル[…]

曙とともにデジタルエクセレンスへの道筋を描く

世界の自動車業界がパンデミックによってもたらされた課題への適応を進める中、PT. Akebono Brake Astra Indonesia(AAIJ)は、スマートインダストリー準備指数(Smart Industry Readiness Index)を活用し、デジタルトランスフォーメーションの取り組みを新たなレベルへと引き上げています。AAIJは、革新的な技術と持続可能な慣行を取り入れることで、ブレーキパッド分野における変化する需要に対応しています。スマートインダストリー準備指数を活用することで、AAIJは製造プロセスを最適化するだけでなく、パンデミック後の環境における回復力と競争力を強化しています。この先進的なアプローチが、AAIJが新たなベンチマークを設定する上でどのように役立っているのか、そしてそれがブレーキパッドと自動車部品業界の未来にどのような意味を持つのかをご覧ください。

横河電機の認定SIRIアセッサーによる産業変革

パートナーである横河電機株式会社との共同制作による新たなマーケティング映像を公開できることを大変嬉しく思います。世界最多のCSA数を誇る横河電機は、SIRIフレームワークへの献身と価値あるソリューション提供へのコミットメントにおいて比類のない存在です。この映像は、横河電機の認定Smart Industry Readiness Index(SIRI)アセッサー(CSA)であるアリシア・フイ氏の輝かしい軌跡を紹介するものであり、横河電機のソリューションがどのように産業の卓越性を推進し、この分野のリーダーとしての地位を確固たるものにしているのかを直接ご覧いただく絶好の機会となります。アリシア氏はエンジニアリングとコンサルティングサービスに関する豊富な知識を持ち、横河電機とその[…]にとってかけがえのない存在です。

SEW-EURODRIVEは、スマートインダストリー準備指数により柔軟性と生産性を向上

急速に変化する世界において、企業が生き残り、繁栄していくためには、柔軟性と俊敏性が不可欠です。これを実現するために、SEW-EURODRIVEはインダストリー4.0の適用を通じてシンガポールの施設を近代化する必要がありました。柔軟性と生産性の向上を目指し、変化と変革を推進することに尽力するSEW-EURODRIVEは、Smart Industry Readiness Indexを活用して重点分野を特定し、変革ロードマップを策定し、リソースを効率的に配分することで、最大限の効果を発揮できるようにしました。真に未来志向の組織となることを目指し、SEW-EURODRIVEが改善ロードマップを策定する上で、Smart Industry Readiness Indexがどのように重要な役割を果たしたのかをご覧ください。

ロックウェル・オートメーション、スマートインダストリー準備指数で業界変革を推進

ロックウェル・オートメーションは、産業オートメーションと情報技術を専門とする世界最大の企業です。その使命は、スマートマニュファクチャリングとデジタルトランスフォーメーションソリューション(アーキテクチャ、ソフトウェア、制御製品およびソリューションを含む)を通じて、環境の持続可能性を維持しながら生産性を向上させることで、世界の生活の質を向上させることです。シンガポールに拠点を置く子会社、ロックウェル・オートメーション・アジア・パシフィック・ビジネスセンター(RA APBC)は、この地域を代表する電子機器メーカーであり、主にプリント基板アセンブリの技術と製品を扱っています。持続可能性は同社のブランドの中核を成す理念であり、RA APBCは生産プロセスと日常業務における廃棄物を削減する新たな方法を模索していました。SIRIがどのように[…]

スマート産業準備指数に注目:ハイアールグループのデジタル化プログラムの検証

ハイアールグループは、自社施設のインダストリー4.0への成熟度をより深く理解するため、複数拠点を対象とした公式スマートインダストリー準備指数評価を実施しました。この評価により、ハイアールは自社の業務における盲点を明らかにし、自社施設のインダストリー4.0への変革を業界標準や競合他社と比較することができました。強みと改善の機会を特定することで、ハイアールは進捗状況を検証し、市場における競争力を高めるための情報に基づいた意思決定を行うことができました。ハイアールがスマートインダストリー準備指数を活用してデジタル化プログラムを検証した方法については、以下のビデオをご覧ください。

スマートインダストリー準備指数に注目:Pepperl+Fuchsのデジタル変革目標設定を支援

ドイツの産業技術企業Pepperl+Fuchsは最近、スマートインダストリー準備指数(SIRI)を活用し、複数の製造拠点における第四次産業革命(4IR)への準備状況を評価しました。公式スマートインダストリー準備指数評価を通じて、Pepperl+Fuchsは自社拠点の一つの成熟度プロファイルが業界平均を下回っていることを発見しました。詳細な評価レポートは、拠点が遅れている領域に関する貴重な洞察を提供し、具体的な改善提案を示しました。スマートインダストリー準備指数評価は、特に注意が必要な重要な領域を浮き彫りにし、Pepperl+Fuchsに拠点の4IR準備状況を向上させるための明確なロードマップを提供しました。これらの主要領域に注力することで、同社は製造業の生産性向上を目指しています[…]

スマートインダストリー準備指数に注目:製造業におけるデジタル変革を加速させるために組織と政府がいかに協力するか

多国間組織や政府は協力して、製造業者のデジタル変革の取り組みを支援することができます。

CONNSTEPはスマートインダストリー準備指数を活用してコネチカット州の製造業の変革を推進しています

米国コネチカット州の製造業は、インダストリー4.0の導入において大きな課題に直面しています。インダストリー4.0技術への移行は大企業にしか実現可能ではないという認識が一般的で、多くの中小企業はその目標と真の可能性について誤解しています。家族経営の中小企業が業界の大部分を占めるコネチカット州では、多くの企業がこれらの先進技術を探求し導入するためのリソース、専門知識、そして自信を欠いています。世界的なパンデミックは、ソーシャルディスタンス対策による工場の人員削減や、継続的なサプライチェーンへの圧力による操業への負担など、これらの課題をさらに深刻化させています。その結果、コネチカット州の製造業は、インダストリー4.0に関する知識を緊急に必要としています。[…]