The global manufacturing sector is one of the largest single emitters of greenhouse gasses (GHG) in the world, responsible for two-thirds of the world’s total GHG emissions. But it’s heartening to note that recent advancements in manufacturing technology and increasing commitment towards more sustainable, eco-efficient processes have helped the industry reduce Scope 1, 2 and 3 emissions across the board – and made a start on addressing Scope 4 emissions too.

What are Scope 1, 2, 3 and 4 emissions?

- Scope 1: covers direct GHG emissions from sources owned and controlled by the company. Common activities include fuel combustion; physical or chemical processing; transportation of materials, products, waste and employees; and fugitive emissions.

- Scope 2: covers indirect GHG emissions caused by the generation of purchased electricity used for Scope 1 activities.

- Scope 3: covers indirect GHG emissions caused by upstream or downstream activities in a company’s wider value chain, such as extraction of raw materials (upstream) or waste disposal (downstream). One company’s Scope 1 and 2 emissions are another company’s Scope 3.

- Scope 4: covers emissions avoided due to the use of a company’s product. Unlike Scopes 1-3, the higher a company scores on Scope 4 emissions the better. Scope 4 was introduced to provide a more holistic calculation of a product’s positive climate impact. It is relatively new and is not officially recognised by the GHG Protocol.

Industry 4.0: helping global manufacturing reduce its carbon footprint

Progressions in technology, including the advancement of digital and analytics tools, have resulted in more eco-efficient manufacturing processes and reduced emissions.

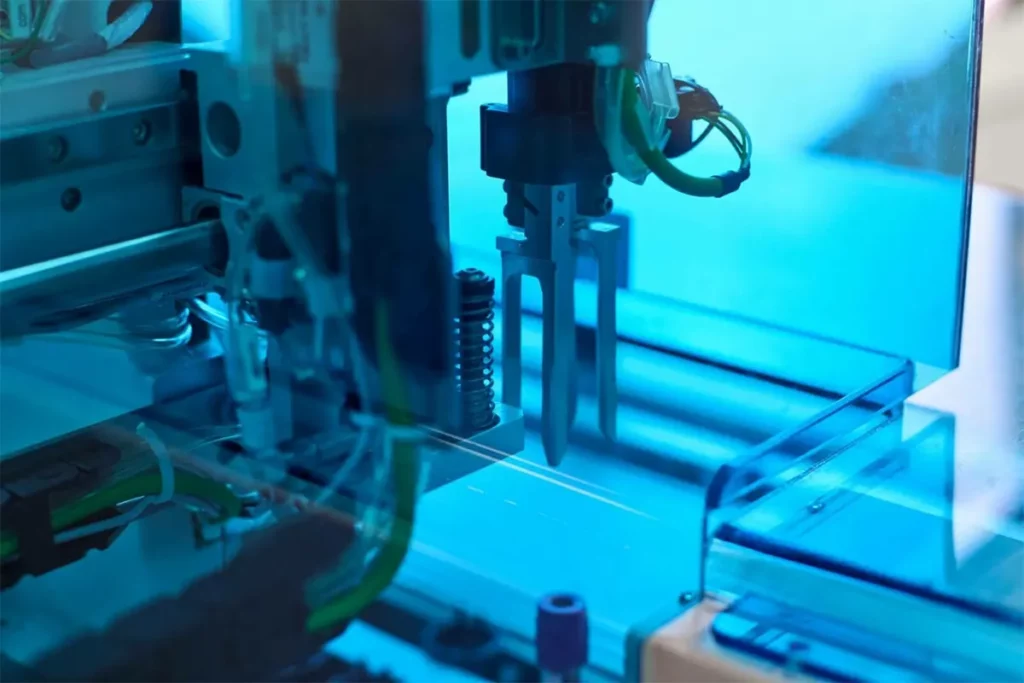

The manufacturing industry is also leveraging Industry 4.0 technologies such as the Internet of Things (IoT), machine learning, artificial intelligence (AI) and automation to track, monitor and improve resource use for a lighter carbon footprint.

Several case studies presented by the World Economic Forum illustrate this.

Ericsson’s smart factory in Lewisville, Texas, in the US showcases how manufacturers are integrating green energy and data solutions to ‘reduce, reuse, recycle’, simultaneously cutting Scope 1 and 2 emissions while improving productivity.

On-site solar panels and rainwater cooling tanks reduce the need for purchased electricity (Scope 2), while a 4G/5G sensor network monitors and analyses energy consumption, automatically powering equipment on or off as required (Scope 1).

With sustainability-related metrics being increasingly scrutinised by investors, stakeholders and consumers alike, manufacturers have also been paying greater attention to the Scope 3 emissions of their partners, suppliers and distributors.

To tackle this, Western Digital in Prachinburi, Thailand combined IoT-connected sensors and machine learning technology to track real-time logistics data and develop a shipment and logistics optimiser. They effectively eliminated unnecessary shipments, improved route efficiencies and reduced transport-related Scope 3 emissions.

The multi-faceted nature of sustainability in manufacturing

While tracking emissions across the end-to-end value chain is highly complex, with multiple tiers of raw materials and sub-components to factor in and Scope 4 emissions even further beyond the control and access of manufacturers, addressing Scope 3 emissions remains one of the most critical ways to reduce the global industry’s carbon footprint.

This is especially important as manufacturing supply chain emissions are over 11 times more than operational emissions.

Consequently, the key to more successful reduction of Scope 1, 2 and 3 emissions – and addressing Scope 4 emissions – is data sharing and transparency.

Global collaboration is needed to share emissions-related information so that manufacturers can better measure and monitor their chain-wide carbon footprint – and identify the most impactful ways to reduce it.

Learn more about the work that we’ve been doing to help global manufacturers transform to achieve better outcomes for all here.