这 德勤的研究强调,制造业的技能差距持续扩大,210 万个职位空缺将给美国带来约 15 万亿美元的损失 2030年 我们知道,当前和未来人才短缺的原因有很多,主要包括劳动力老龄化、技术进步但技能跟不上,以及对制造业角色的过时看法。 让人想起电影中描绘的危险、乏味的工作条件 美国小说家厄普顿·辛克莱的《丛林》。

根据 美国商会, 制造业仍有 45% 的职位空缺尚未填补。 世界经济论坛2023年就业前景展望 报告强调,预计未来五年先进制造业的40项现有技能要求将发生变化。根据一项调查,领导者已经敲响了警钟。 全国制造商协会(NAM),近75%的制造业经理认为熟练劳动力短缺是他们面临的主要业务挑战。

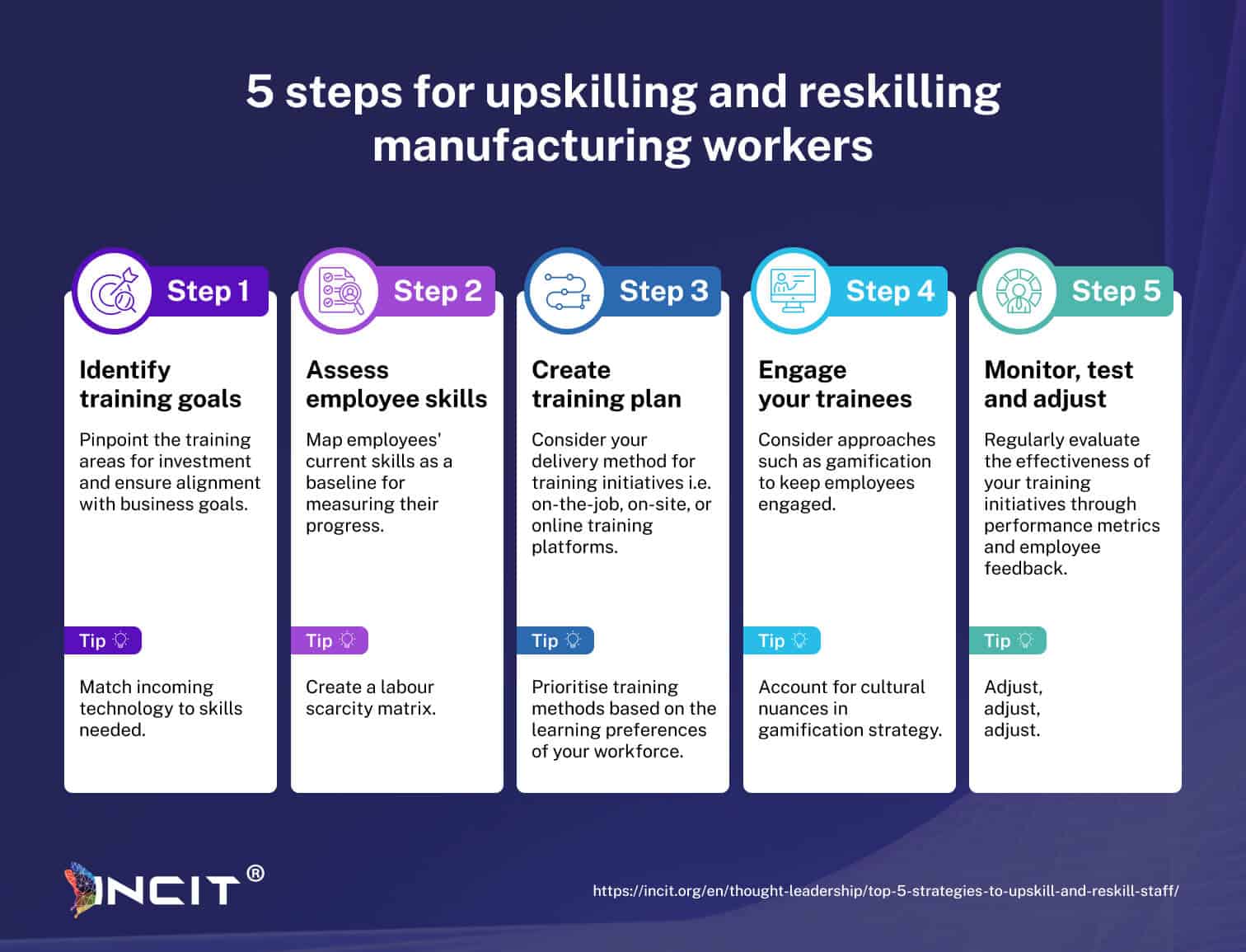

制造商正面临严重的劳动力短缺问题,亟待解决。但企业该如何应对迫在眉睫的人才危机呢?下文将探讨通过有针对性的技能提升计划赋能员工的关键步骤,确保企业在劳动力挑战面前保持韧性和增长。

通过战略性技能提升计划培养面向未来的劳动力

制造业劳动力短缺问题如今已成普遍现象,预计还会进一步恶化。制造企业必须投资技能提升和技能再培训计划。通过实施与不断变化的工作岗位相适应的有针对性的培训项目,并利用游戏化等创新方法(利用游戏化让技能再培训更具吸引力!),制造商可以增强员工的适应能力,从而缓解企业劳动力短缺问题。采取这些策略不仅可以弥补技能差距,还能帮助制造企业在全球市场上保持持续增长和竞争力。

此外,还有专门的培训项目,例如 西里/科西里 程序 提供方 INCIT,可以通过此认证支持领导者持续发展技能,从而推动制造业的数字化和可持续发展实践。采用这些策略不仅可以弥补技能差距,还能帮助制造企业在全球市场中保持持续增长和竞争力。

关于制造业技能提升和再培训的常见问题

提升技能和再培训的四种策略是什么?

制造业技能提升和再培训的四个关键策略是:

- 在职培训

- 数字学习平台

- 产学合作

- 认证项目

这些方法有助于工人获得智能制造和工业 4.0 的新技能。

为什么技能提升在制造业中很重要?

提升技能对于制造业来说非常重要,因为它可以帮助工人适应新技术、提高生产力并在快速变化的工业 4.0 环境中保持竞争力。

制造业中的技能提升和技能再培训有何区别?

技能提升是指学习新技能以在现有岗位上发展,而技能再培训则是指培训员工胜任全新岗位。两者对于制造业而言都至关重要,有助于支持数字化转型和自动化。

制造商如何打造面向未来的劳动力?

制造商可以通过投资持续培训、采用数字工具、建立学习文化以及将劳动力发展与工业 4.0 技术相结合来打造一支面向未来的劳动力队伍。

制造商在员工培训方面面临哪些挑战?

制造商面临的挑战包括培训预算有限、缺乏数字素养、劳动力老龄化以及难以跟上智能制造快速变化的技术。

智能制造技能提升的例子有哪些?

智能制造技能提升的例子包括培训工人使用机器人、数据分析工具、数字孪生、物联网平台和基于人工智能的生产系统。

工业 4.0 如何影响劳动力规划?

工业 4.0 通过将需求转向精通技术的角色、要求新技能以及推动制造商重新思考培训、招聘和人才保留策略来影响劳动力规划。

制造业劳动力转型的最佳实践是什么?

劳动力转型的最佳实践包括技能差距评估、个性化学习路径、领导力发展、与技术提供商的合作以及与工业 4.0 目标相关的绩效跟踪。