Data has been captured in various forms and has been an essential part of processes for centuries – from simple tallying markers and notes to complex spreadsheets and cloud storage. Today, the amount and volume of complex data, or big data, that is created and stored is staggering, with an estimated 2.5 billion gigabytes generated daily.

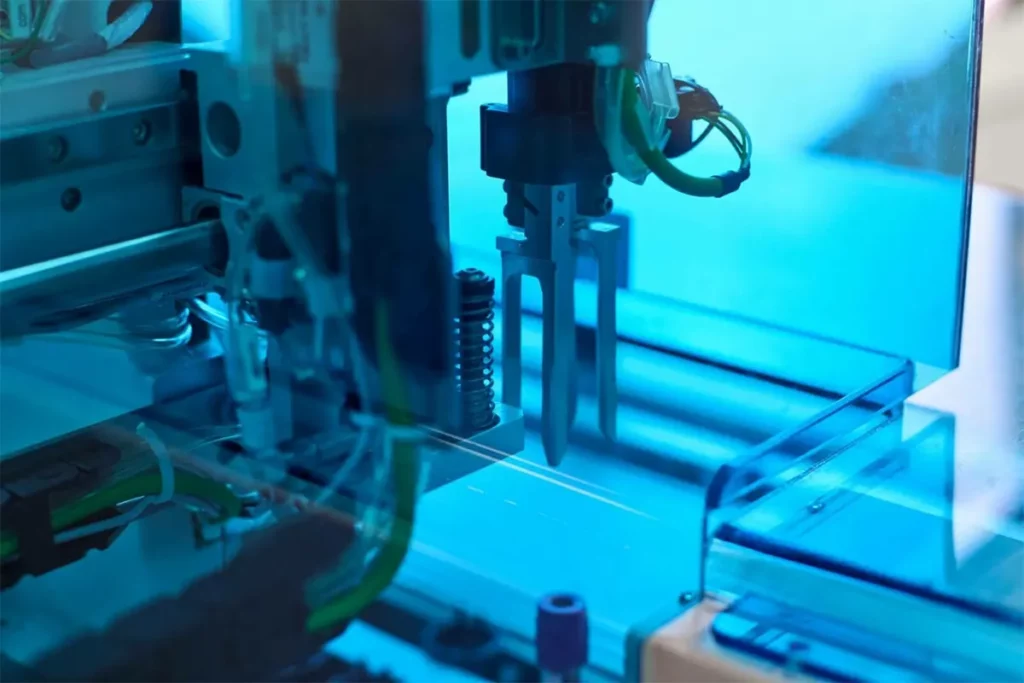

In manufacturing, there is a rapidly growing amount of data that is created and distributed with smarter and interconnected technologies like artificial intelligence (AI), machine learning (ML) and Internet of Things (IoT) devices now integrated into operational systems.

However, without a proficient grasp of big data utilisation and analysis, the data will be reduced to mere numbers.

Between the use of these smart manufacturing technologies and managing traditional datasets, manufacturers have more data points on the shop floor than ever before. For them, getting greater returns on their technology investments going forward will come down to having sophisticated analytical models in place as this will enable them to define, study and draw tangible conclusions from the data to make the right decisions for optimal business outcomes. By using the right analytics levers, no data gets left behind on the table.

If automation is about efficiency, then analytics is about intelligence

The discussions around modern manufacturing often revolve around technologies that are designed to automate processes to enable operational efficiencies at scale. With the advent of Industry 4.0, we have been witnessing the speed of this technology adoption increasing, and the rate of digital transformation has accelerated even further since the COVID-19 pandemic kicked digitalisation into higher gear.

Many businesses are now making the effort to drive greater efficiency with the help of intelligent tools and solutions. However, making the distinction between efficient and intelligent is vital.

For instance, powerful IoT sensors have increased process efficiency by enabling the ability to monitor and record manufacturing assets in real-time, like tracking the location and contents of bins at production facilities virtually and automating stock replenishment on-demand.

However, the use of powerful analytics introduces a higher level of intelligence that facilitates optimisation. Data analytics allows the manufacturer to identify areas for further efficiency and cost reduction – whether that’s by rearranging production line sequences, re-configuring the product using parts from that bin, or suggesting more economical components.

Thanks to data analytics, manufacturers can now get one step closer towards their continuous improvement and process optimisation targets, making it another key characteristic of intelligent factories. It is therefore crucial for manufacturing companies to leverage data effectively, adding another layer of intelligence to their operations to help them identify and fix gaps while enhancing existing processes. Although it may be a challenge for some, this can be achieved by implementing benchmarking frameworks and tools such as the Smart Industry Readiness Index (SIRI) so companies can drive and scale digital transformation and improve their operations and processes even further.

From fully automated factories to autonomous manufacturing ecosystems

Manufacturing has seen its fair share of change over the years, evolving significantly with each new wave of disruption. The shift from investing in new technologies on an ad-hoc basis to building intelligent factories with a fleshed out digital transformation plan from the ground up is already underway. But visionary industry leaders want to know what is next and the steps that are needed to get there.

As more data is harnessed and analysed by the modern factories of the future, these factories also begin to learn how to evaluate contexts, adapt to constraints, and take actions that most closely align to outcomes predefined by the organisation – with little to no human intervention.

Over time, the power of data analytics and automation can power the next generation of smart factories, leading to truly autonomous manufacturing ecosystems that are a culmination of early Industry 4.0 efforts. While Industry 5.0 is still on the distant horizon, the dawn of autonomous manufacturing ecosystems would be a clear step up from Industry 4.0.

The starring role played by cutting-edge data analytics is set to become the defining characteristic of this next era in manufacturing where production can seamlessly balance mass production with demand for customisation.

Data analytics: the backbone of manufacturing transformation

Digital transformation and smart and interconnected technologies have delivered greater levels of success to the manufacturers of today than before. Throughout the digitalisation process, advanced machinery and complex systems, along with big data, AI, ML and IoT, have helped to power next-generation factories and maximise their capabilities. However, the mountains of data generated in a modern factory would not be useful without the important backbone of data analytics to interpret and extrapolate critical information that can be acted on.

With data analytics, the factories of the future and fully autonomous ecosystems can become a reality as part of an advanced stage of Industry 4.0. However, for manufacturers to get to this next phase, they must understand where they’re lacking and how they can address potential gaps. With SIRI, well-defined industry-specific benchmarks and clear roadmaps will pave the way towards the transformation that manufacturers seek.

Want to undergo a SIRI assessment to see how your company fares among your peers? Visit https://siri.incit.org/assessment/request-assessment or contact us at [email protected] to learn more.