Industrial Artificial Intelligence Maturity Readiness Index

Introducing AIMRI

AI adoption is rapidly transforming the manufacturing landscape, yet many companies struggle to scale AI effectively. Challenges such as siloed data, unclear AI strategy, and workforce readiness hinder progress.

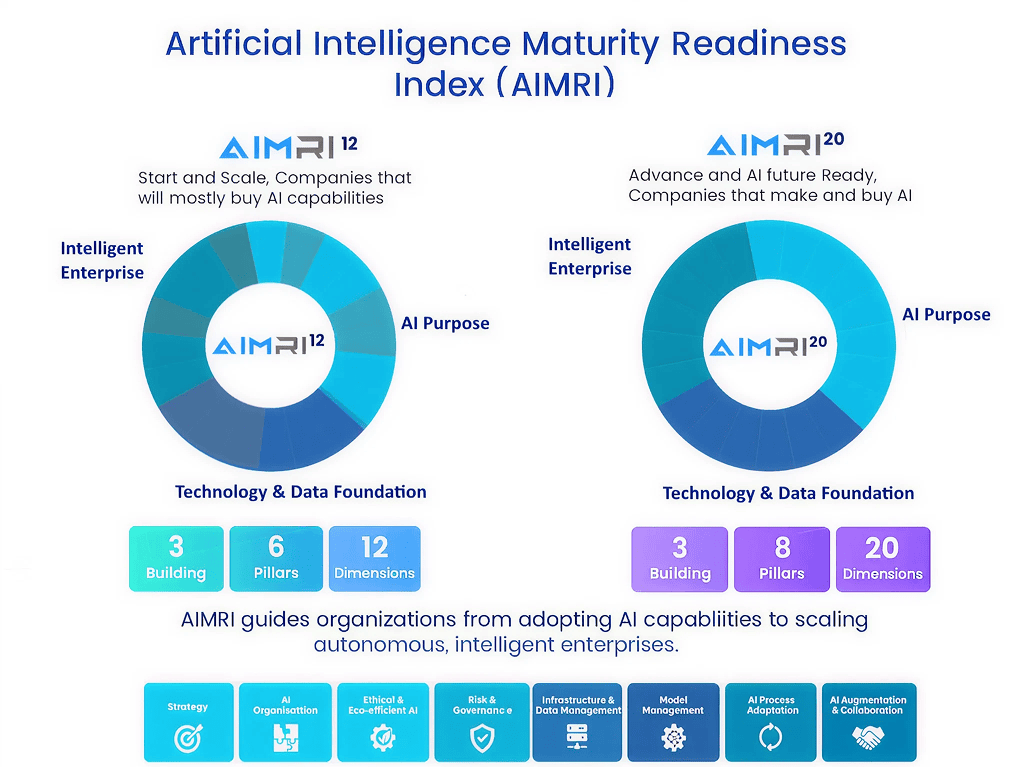

The Industrial Artificial Intelligence Maturity Readiness Index (AIMRI) is designed to help manufacturers systematically assess and enhance their AI capabilities. Developed by INCIT and Detecon, AIMRI evaluates AI readiness across 20 key dimensions, spanning strategy, governance, data infrastructure, and AI applications in operations, supply chain, and product lifecycle management.

AIMRI provides a structured roadmap to prioritise AI investments, align stakeholders, and drive measurable improvements. Through detailed assessment and benchmarking against best practices, AIMRI delivers insights to accelerate AI adoption and unlock competitive advantages.

Ready to Start your AI Journey?

Assess your AI Readiness with AIMRI and position your organisation for AI-driven success.

AI Potential In Manufacturing

AI Investments by leaders compared to their peers

Overcoming Manufacturing AI Adoption Challenges

AI adoption presents several significant challenges for manufacturers. A common hurdle is the lack of transparency in identifying key areas for improvement, leaving many unsure where AI can deliver the most value. Laying the groundwork for AI is also complex, especially when organisations must coordinate efforts across departments while managing legacy systems alongside emerging AI technologies. The intricate nature and interdependencies of AI systems further complicate integration efforts.

Adding to the challenge, many AI initiatives fail to demonstrate measurable impact. Even when pilot projects succeed in one facility, manufacturers often struggle to scale those solutions across other plants due to inconsistent infrastructure and varying levels of digital maturity.

Our Methodologies

Lead Framework

Transforming and upgrading an enterprise for Industrial AI is not a one-time initiative but a continuous, circular journey.

The LEAD Framework encapsulates this transformation through a 4-step cyclical process that organisations can adopt to learn, evaluate, architect, and deliver sustainable AI-driven transformation.

The LEAD Framework provides a structured yet adaptive approach to guide organisations through every stage of their Industrial AI transformation journey, ensuring lasting impact and scalability.

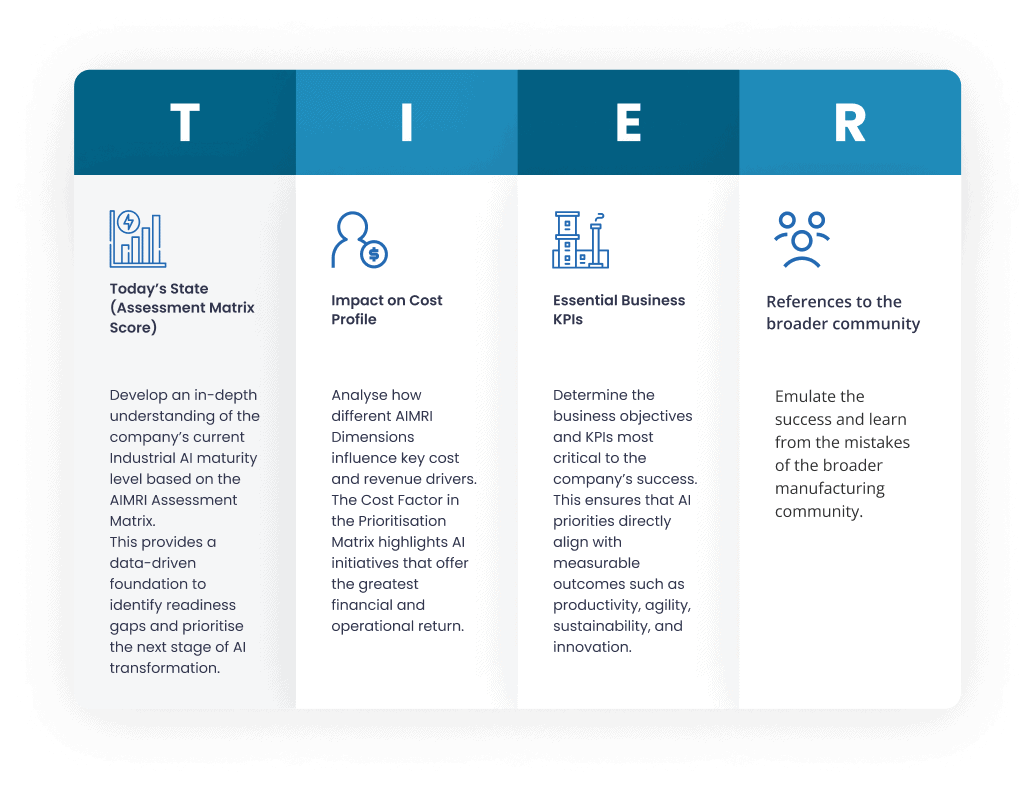

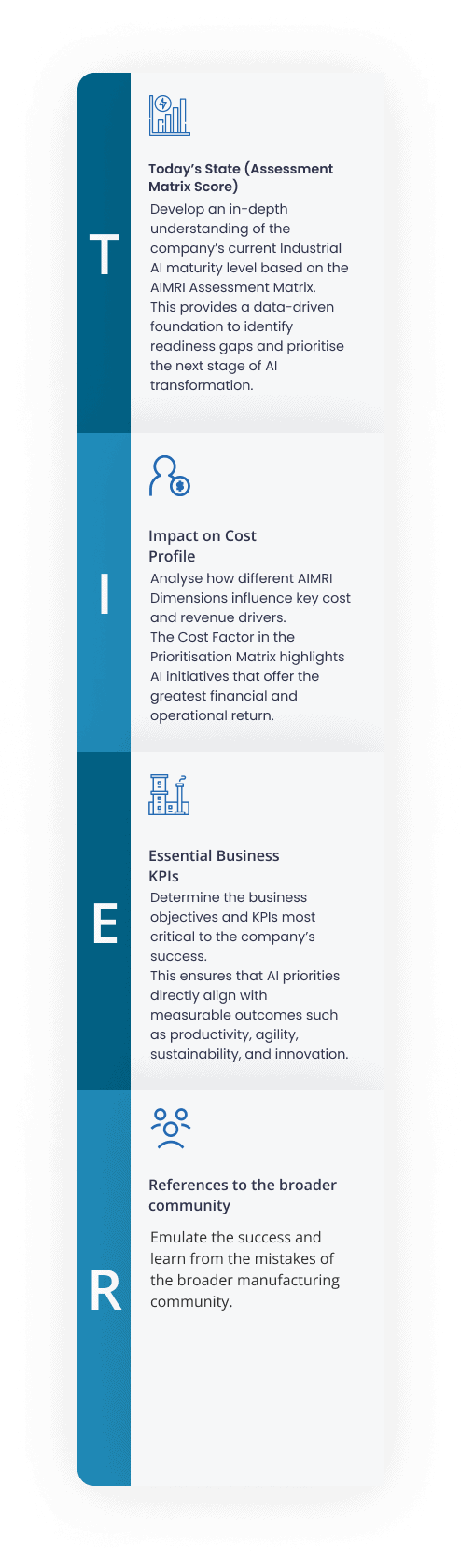

TIER Framework

To formulate effective Industrial AI transformation roadmaps, prioritisation is essential. The TIER Framework defines four guiding principles that help organisations identify where AI adoption delivers the greatest impact.

By combining insights from the AIMRI Assessment Matrix and the Prioritisation Matrix, manufacturers can strategically focus their AI investments to maximise business value, efficiency, and competitiveness.

The AIMRI TIER Framework translates AI maturity insights into prioritised, actionable strategies—bridging readiness assessment with measurable transformation outcomes.

Assessment Matrix

The AIMRI Assessment Matrix is the world’s first AI-centric readiness and maturity assessment framework, designed to balance technical depth, usability, and real-world relevance. It features six progressive maturity bands across 20 interlinked AI Dimensions, each representing a defined stage of Industrial AI development within an organisation. Together, these bands provide a proof-based snapshot of an enterprise’s current AI maturity level, known as the AIMRI Assessment Matrix Score, enabling evidence-driven benchmarking and transformation planning.

Successful AI-driven transformation begins with a clear understanding of the components that define future-ready manufacturing.

The AIMRI Framework is structured across three integrated layers — encompassing three core Building Blocks, eight strategic Pillars, and twenty Dimensions that collectively evaluate an organisation’s Industrial AI readiness across AI Purpose, technology, and operations.

Prioritise Matrix

AIMRI Prioritise Matrix

The AIMRI Prioritisation Matrix is a data-driven management tool that helps organisations translate AI maturity insights into actionable priorities. It evaluates three key factors — cost impact, critical business KPIs, and proximity to best-in-class benchmarks — to identify the most valuable areas for Industrial AI advancement. These factors are derived from four structured inputs aligned with the TIER Framework principles, ensuring that prioritisation decisions are strategic, measurable, and outcome-oriented.

Lead

Framework

Transforming & a manufacturing facility

TIER

Framework

Key concepts tools behind AIMRI

Assessment

Matrix

First Manufacturing AI self-diagnostic tool

Prioritise

Matrix

directional tool designed for management planning

How AIMRI Works for You?

Intelligence Enterprise as the Lever

01

AI Process Adaptation

Integrate AI to optimise workflows, decision-making, and efficiency across operation managements, supply chain, and product lifecycle management.

Technological Enablers

03

Technology Infrastructure & Data Management

Integration, connectivity, security, storage, scalability, computing, AI interfaces, Data lineage, metadata, data processes, data quality, data diversity, feature engineering.

04

Model Management

Model reliability, performance, and version control.

Organisational Enablers

05

AI Strategy

Data & AI strategy, business buy-in, resource allocation, AI portfolio, innovation, ecosystem collaboration.

06

AI Organisation

Leadership involvement, chage management, AI culture, knowledge management, upskilling.

07

Ethical & Eco-efficient AI

Fairness, human rights, transparency, accountability, social and environmental impact.

08

Risk & Governance

Regulation adherence, risk management, compliance and governance framework, training, audits.

AIMRI’s Six Key Differentiators

Next Generation Beyond

Smart Industry Readiness Index (SIRI)

01

Evolutionary Leap from digital maturity to AI-Powered intelligence with performance-linked outcomes

AI-Specific Focus

03

Dedicated evaluation of Al-centric maturity across strategy, organization, and operational integration Interlinked Dimensions

Interlinked Dimensions

05

First framework showing Al dimension interdependencies with progressive KPI roadmaps

Independent & Holistic Framework

02

Comprehensive 20-dimension model developed by leading institutions, vendor-neutral approach

Proof-Based Maturity Model

04

Evidence-based assessments with verifiable proof points and performance validation through Enterprise Performance Impact KPIs (EPIK)

Global Benchmarking Impact

06

Enables national Al readiness comparison and policy development for economic sustainability

Next-Generation Beyond Smart Industry Readiness Index (SIRI)

01

Evolutionary Leap from digital maturity to AI-Powered intelligence with performance-linked outcomes

Independent & Holistic Framework

02

Comprehensive 20-dimension model developed by leading institutions, vendor-neutral approach

AI-Specific Focus

03

Dedicated evaluation of Al-centric maturity across strategy, organization, and operational integration Interlinked Dimensions

Proof-Based Maturity Model

04

Evidence-based assessments with verifiable proof points and performance validation through Enterprise Performance Impact KPIs (EPIK)

Interlinked Dimensions

05

First framework showing Al dimension interdependencies with progressive KPI roadmaps

Global Benchmarking Impact

06

Enables national Al readiness comparison and policy development for economic sustainability

Next-Generation Beyond

Smart Industry Readiness Index (SIRI)

Smart Industry Readiness Index (SIRI) established the global benchmark for Industry 4.0 readiness, focusing primarily on digital productivity and smart manufacturing practices. AIMRI takes the next evolutionary leap by focusing not just on digital maturity, but on AI-powered intelligence covering strategy, organisation, data, ethics, and operational integration. With EPIK (Enterprise Performance Impact KPIs), AIMRI connects readiness maturity directly to business performance outcomes like OEE, sustainability, and autonomous operations.

Independent & Holistic Readiness Framework

Unlike proprietary vendor-led models, AIMRI is independent, developed by INCIT and Detecon with scientific advisors from leading institutions (TUM, Maryland, Tecnológico de Monterrey). Covers 20 Dimensions across Strategy, Organisation, Ethics, Risk, Technology, and Enterprise Operations, making it the most comprehensive AI-readiness framework globally. EPIK strengthens the framework's independence by providing neutral, evidence-based KPIs that are globally applicable and not tied to vendor technologies or narrow industry standards.

AI-Specific Focus

AIMRI uniquely evaluates AI-centric maturity not just digital transformation. Covers AI Strategy, AI Organisation, Model Management, AI Lifecycle, AI Process Adaptation, and AI Collaboration, making it directly relevant for organisations embedding AI in real manufacturing contexts. With EPIK, AIMRI demonstrates how AI maturity translates into tangible performance improvements from productivity gains (AI-OEE, AI-OLE) to sustainability metrics (Energy Index, Scrap Rate) and future-ready KPIs for Autonomous Operations.

Proof-Based Maturity Model

Each dimension includes Guiding Statements, Proof Points, and Exemplary Markers, offering verifiable, evidence-based maturity assessments. EPIK complements this by adding performance validation — measurable KPIs confirm whether maturity progress results in real-world impact on efficiency, sustainability, and resilience. This makes AIMRI both auditable and results-driven, ensuring credibility for governments, manufacturers, and investors.

Interlinked Dimensions for Real-World Adoption

AIMRI is the first maturity model to show interdependence between AI dimensions (e.g., higher maturity in Operations Management requires sufficient AI Infrastructure maturity). EPIK aligns with these interdependencies, providing stage-based KPIs that evolve as maturity advances (e.g., AI-Enhanced OEE at early stages, Autonomous Operation Rate at advanced stages). This ensures organisations receive a progressive roadmap linking readiness maturity → performance outcomes → strategic priorities.

Global Benchmarking & Policy Impact

AIMRI is designed not only for companies but also for national benchmarking — enabling policymakers to compare AI readiness across industries and countries. With EPIK integration, policymakers can go a step further: they can measure not just readiness, but also the economic and sustainability impact of AI adoption across regions and sectors. Together, AIMRI and EPIK provide the foundation for AI-related incentives, education strategies, ESG integration, and national industrial policies.

Who Can Benefit from AIMRI?

Manufacturing Companies

Unlock the Power of AI in Manufacturing

AIMRI enables manufacturers to assess their AI readiness across strategic, operational, and technological dimensions — helping them transform from automated to intelligent, self-optimising operations. How AIMRI Helps:

- Discover AI opportunities in production, supply chain, and quality functions.

- Benchmark performance against industry peers and best-in-class leaders.

- Build a data-driven roadmap for industrial AI adoption.

- Accelerate ROI with focused investments in AI capabilities.

- Empower your workforce through intelligent decision-support systems.

Governments

Shape the Future of Industrial AI

AIMRI supports governments and policymakers in driving national AI strategies that foster sustainable industrial growth and competitiveness. How AIMRI Helps:

- Benchmark national or regional AI readiness in manufacturing.

- Identify sectoral strengths, gaps, and transformation opportunities.

- Design data-driven policies for AI talent, innovation, and infrastructure.

- Support incentive programs that accelerate AI adoption.

- Strengthen collaboration between industry, academia, and research ecosystems.

Technology and Consultancy Firms

Deliver Measurable AI Impact for Clients

AIMRI offers technology and consulting firms a globally standardised framework to assess AI maturity and design transformation roadmaps for their clients.How AIMRI Helps:

- Integrate a proven, evidence-based methodology into consulting services.

- Enhance offerings in AI strategy, digital transformation, and analytics.

- Provide benchmarking insights that accelerate client adoption journeys.

- Co-create tailored AI maturity programs and capability-building initiatives.

- Drive recurring value through AIMRI-based assessments and continuous improvement plans.

Equity Companies

Invest Smarter with AI Readiness Insights

AIMRI helps investors and equity firms evaluate the AI maturity and competitive potential of manufacturing and industrial assets. How AIMRI Helps:

- Assess digital and AI capabilities during investment due diligence.

- Identify growth opportunities through AI-driven value creation.

- Guide investment strategies with objective AI maturity insights.

- Track portfolio performance on productivity and sustainability KPIs.

- Support targeted funding for AI transformation and innovation.