The jurang kemahiran yang ketara dalam pembuatan terus melebar, seperti yang ditegaskan oleh penyelidikan Deloitte, yang mendapati bahawa 2.1 juta pekerjaan yang tidak diisi akan mengakibatkan kos kira-kira $1 trilion kepada Amerika Syarikat pada tahun 2030 bersendirian. Kami tahu terdapat pelbagai sebab untuk kekurangan bakat semasa dan masa depan, terutamanya disebabkan oleh tenaga kerja yang semakin tua, kemajuan teknologi dengan set kemahiran yang tidak mengikuti perkembangan dan pandangan ketinggalan zaman tentang rupa peranan dalam pembuatan. mengingatkan keadaan kerja yang berbahaya dan tidak menarik yang digambarkan dalam "The Jungle" oleh novelis Amerika, Upton Sinclair.

Menurut Dewan Perniagaan AS, 45 peratus daripada pembukaan pekerjaan dalam sektor perkilangan masih tidak dipenuhi. Masa Depan Pekerjaan 2023 Forum Ekonomi Dunia laporan menyerlahkan bahawa 40 daripada keperluan kemahiran semasa dalam pembuatan termaju dijangka berkembang dalam tempoh lima tahun akan datang. Pemimpin telah membunyikan penggera, menurut tinjauan oleh Persatuan Pengilang Kebangsaan (NAM), hampir 75 peratus pengurus pembuatan menyebut kekurangan tenaga kerja mahir sebagai cabaran perniagaan utama mereka.

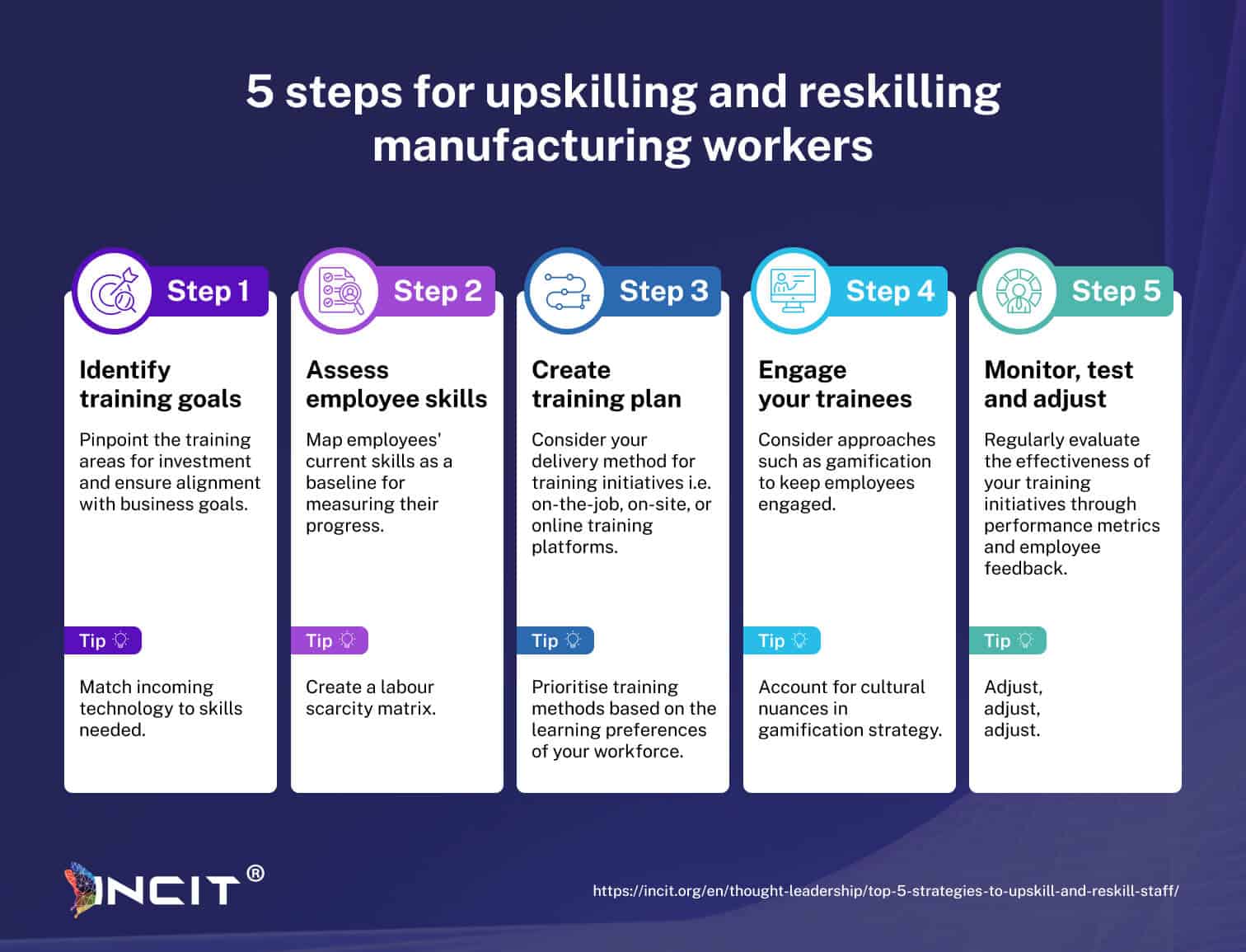

Pengilang sedang bergelut dengan kekurangan buruh yang ketara yang memerlukan perhatian segera, tetapi apakah yang boleh dilakukan oleh perniagaan untuk bersedia menghadapi krisis bakat yang semakin hampir? Di bawah, kami meneroka langkah-langkah utama untuk memperkasakan pekerja melalui program peningkatan kemahiran yang disasarkan, memastikan daya tahan dan pertumbuhan dalam menghadapi cabaran tenaga kerja.

Memupuk tenaga kerja sedia masa hadapan melalui inisiatif peningkatan kemahiran strategik

Kekurangan tenaga kerja dalam sektor pembuatan kini endemik dan dijangka bertambah buruk. Adalah penting bagi syarikat pembuatan untuk melabur dalam inisiatif peningkatan kemahiran dan kemahiran semula. Dengan melaksanakan program latihan yang disasarkan sejajar dengan peranan pekerjaan yang berkembang dan memanfaatkan kaedah inovatif seperti gamifikasi (gunakannya untuk menjadikan kemahiran semula lebih menarik!), pengilang boleh memperkasakan tenaga kerja mereka untuk menyesuaikan diri, dengan itu mengurangkan kekurangan buruh dalam perniagaan. Menerima strategi ini bukan sahaja akan merapatkan jurang kemahiran tetapi juga meletakkan firma pembuatan untuk pertumbuhan dan daya saing yang mampan dalam pasaran global.

Tambahan pula, program latihan khusus, seperti SIRI/COSIRI Program ditawarkan oleh INCIT, boleh menyokong pemimpin dengan pembangunan kemahiran berterusan mereka dengan pensijilan ini, yang memajukan amalan pendigitalan dan kemampanan dalam pembuatan. Menerima strategi ini bukan sahaja akan merapatkan jurang kemahiran tetapi juga meletakkan firma pembuatan untuk pertumbuhan dan daya saing yang mampan dalam pasaran global.

Soalan Lazim Mengenai Peningkatan Kemahiran dan Kemahiran Semula dalam Pembuatan

Apakah 4 Strategi untuk Peningkatan Kemahiran dan Kemahiran Semula?

Empat strategi utama untuk meningkatkan kemahiran dan kemahiran semula dalam pembuatan ialah:

- Latihan di tempat kerja

- Platform pembelajaran digital

- Perkongsian industri-akademik

- Program pensijilan

Pendekatan ini membantu pekerja memperoleh kemahiran baharu untuk pembuatan pintar dan Industri 4.0.

Mengapakah Peningkatan Kemahiran Penting dalam Pembuatan?

Peningkatan kemahiran adalah penting dalam pembuatan kerana ia membantu pekerja menyesuaikan diri dengan teknologi baharu, meningkatkan produktiviti dan kekal berdaya saing dalam persekitaran Industri 4.0 yang berubah dengan pantas.

Apakah Perbezaan Antara Peningkatan Kemahiran dan Kemahiran Semula dalam Pembuatan?

Peningkatan kemahiran bermaksud mempelajari kemahiran baharu untuk berkembang dalam peranan semasa, manakala kemahiran semula melibatkan latihan pekerja untuk peranan baharu sepenuhnya. Kedua-duanya adalah penting dalam pembuatan untuk menyokong transformasi digital dan automasi.

Bagaimana Pengilang Boleh Mewujudkan Tenaga Kerja Bersedia Masa Depan?

Pengilang boleh mencipta tenaga kerja sedia masa hadapan dengan melabur dalam latihan berterusan, menerima alatan digital, membina budaya pembelajaran dan menyelaraskan pembangunan tenaga kerja dengan teknologi Industri 4.0.

Apakah Cabaran Yang Dihadapi Pengilang dalam Latihan Tenaga Kerja?

Pengilang menghadapi cabaran seperti belanjawan latihan yang terhad, kekurangan celik digital, tenaga kerja yang semakin tua dan kesukaran untuk mengikuti perubahan pantas teknologi dalam pembuatan pintar.

Apakah Contoh Peningkatan Kemahiran dalam Pembuatan Pintar?

Contoh peningkatan kemahiran dalam pembuatan pintar termasuk melatih pekerja menggunakan robotik, alat analisis data, kembar digital, platform IoT dan sistem pengeluaran berasaskan AI.

Bagaimanakah Industri 4.0 Mempengaruhi Perancangan Tenaga Kerja?

Industri 4.0 menjejaskan perancangan tenaga kerja dengan mengalihkan permintaan ke arah peranan yang celik teknologi, memerlukan kemahiran baharu dan mendorong pengilang untuk memikirkan semula strategi latihan, pengambilan pekerja dan pengekalan bakat.

Apakah Amalan Terbaik untuk Transformasi Tenaga Kerja dalam Pembuatan?

Amalan terbaik untuk transformasi tenaga kerja termasuk penilaian jurang kemahiran, laluan pembelajaran yang diperibadikan, pembangunan kepimpinan, perkongsian dengan penyedia teknologi dan penjejakan prestasi yang terikat dengan matlamat Industri 4.0.