Dalam landskap pembuatan yang serba pantas hari ini, pemimpin sedang giat mengubah operasi mereka dengan inovasi termaju, menyepadukan kemampanan dan teknologi dengan lancar selaras dengan Industri 4.0. Pengilang kini mempunyai kuasa untuk merevolusikan proses pembuatan pintar mereka menggunakan penyelesaian teknologi bersih yang canggih.

Mereka sedang menggunakan hidrogen untuk menggerakkan operasi mereka, a robotik untuk mengendalikan barangan halus seperti buah-buahan dan sayur-sayuran, dan beralih kepada pembungkusan mesra alam seperti kotak kulat biodegradasi—ini hanyalah beberapa contoh cara cleantech membentuk semula industri.

Pembuatan pintar bukan hanya tentang mengguna pakai teknologi bersih; ia memacu integrasi pantas, menyediakan perniagaan dengan kelebihan daya saing yang ketara. Penggunaan pantas penyelesaian mesra Alam Sekitar, Sosial dan Tadbir Urus (ESG) ini telah meningkatkan pelaburan dalam pasaran teknologi bersih.

Menurut Commodity Insights S&P Global, pelaburan teknologi bersih tahunan global dijangka melepasi US$900 bilion menjelang 2030, hampir tiga kali ganda perbelanjaan dari 2020.

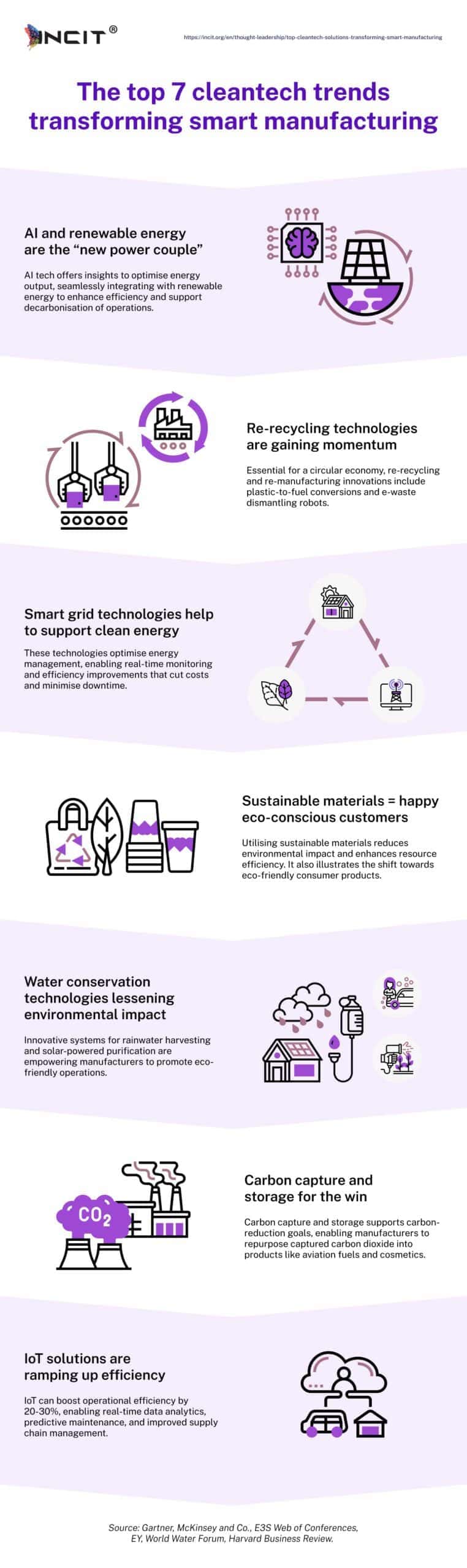

Sektor pembuatan memainkan peranan penting dalam pertumbuhan ini, menyumbang sekitar 0.7 peratus kepada pengembangan segmen. Dengan perbelanjaan oleh pengeluar yang semakin meningkat, tujuh trend teknologi bersih utama telah muncul, menetapkan peringkat untuk transformasi yang memberi kesan:

Memaksimumkan faedah penyelesaian teknologi bersih dalam pembuatan pintar

Inovasi Cleantech menyokong pembuatan pintar dalam pelbagai cara, memastikan pengeluar yakin boleh melabur dalam teknologi cleantech yang berdaya maju dari segi alam sekitar dan ekonomi. Daripada pengeluaran makanan yang mampan kepada plastik terbiodegradasi, cleantech bukan sahaja memberi manfaat kepada kesihatan ESG perniagaan tetapi juga meningkatkan keuntungan.

Dengan memanfaatkan teknologi bersih, pengilang boleh memupuk pembangunan mampan, menggabungkan integriti alam sekitar dengan pertumbuhan ekonomi dan membuka jalan untuk masa depan yang lebih mampan. Dengan kuasa transformatif cleantech, industri pembuatan bersedia untuk era yang lebih hijau dan lebih makmur.

Disahkan oleh Forum Ekonomi Dunia (WEF), yang Indeks Kesediaan Industri Kelestarian Pengguna (COSIRI) bertindak sebagai rangka kerja ESG yang komprehensif, meningkatkan kemampanan dan keterlihatan kemajuan ESG merentas sektor pembuatan. Alat teguh ini memberi kuasa kepada pengeluar untuk mengurus faktor risiko utama dengan lebih berkesan, memberikan kelebihan strategik dan memupuk pertumbuhan jangka panjang.

Soalan Lazim Mengenai Penyelesaian Cleantech yang Mengubah Pembuatan Pintar

Apakah Cleantech dalam Pembuatan Pintar?

Cleantech dalam pembuatan pintar merujuk kepada teknologi yang mengurangkan kesan alam sekitar, meningkatkan kecekapan tenaga dan menggalakkan amalan pengeluaran yang mampan. Ia termasuk inovasi seperti tenaga boleh diperbaharui, sistem pengurusan tenaga, dan teknologi pengurangan sisa.

Bagaimanakah Penyelesaian Cleantech Menyokong Pembuatan Mampan?

Penyelesaian Cleantech menyokong pembuatan mampan dengan mengurangkan pelepasan karbon, mengoptimumkan penggunaan sumber, mengurangkan sisa dan meningkatkan kecekapan tenaga sepanjang proses pengeluaran.

Apakah Penyelesaian Cleantech Teratas Digunakan di Kilang Pintar?

Penyelesaian teknologi bersih teratas di kilang pintar termasuk tenaga solar, robotik cekap tenaga, pengurusan tenaga berkuasa AI, sistem kitar semula air dan teknologi ekonomi bulat yang menggunakan semula bahan.

Mengapakah Cleantech Penting untuk Pembuatan Pintar?

Cleantech adalah penting untuk pembuatan pintar kerana ia membolehkan pencapaian matlamat kemampanan, mengurangkan kos operasi, menyokong pematuhan ESG, dan meningkatkan kecekapan kilang dan tanggungjawab alam sekitar.

Industri Apakah yang Mengguna pakai Cleantech untuk Pembuatan?

Industri yang mengguna pakai teknologi bersih termasuk elektronik, automotif, pemprosesan makanan, tekstil dan industri berat, terutamanya yang ingin mengurangkan pelepasan dan meningkatkan prestasi tenaga.

Bagaimanakah AI Meningkatkan Aplikasi Cleantech dalam Pembuatan?

AI meningkatkan teknologi bersih dalam pembuatan dengan mendayakan penyelenggaraan ramalan, mengoptimumkan penggunaan tenaga, memantau pelepasan dan membuat keputusan masa nyata yang mengurangkan pembaziran dan meningkatkan kecekapan.

Apakah Faedah Menggunakan Cleantech dalam Industri 4.0?

Faedah termasuk pengurangan kesan alam sekitar, pematuhan yang lebih baik terhadap peraturan hijau, penjimatan kos, kecekapan sumber yang lebih baik dan daya saing yang dipertingkatkan dalam ekonomi yang berfokuskan kemampanan.

Bagaimanakah Pembangunan Penyelesaian Cleantech Memajukan Pembuatan Pintar?

Pembangunan penyelesaian teknologi bersih memajukan pembuatan pintar dengan memperkenalkan kaedah pengeluaran yang lebih bersih, sistem cekap tenaga dan alat digital yang mengurangkan kesan alam sekitar dan menyokong pertumbuhan yang mampan.

Apakah Beberapa Contoh Teknologi Bersih dalam Pembuatan?

Contoh teknologi bersih dalam pembuatan termasuk jentera berkuasa solar, sistem pemulihan tenaga, rawatan air gelung tertutup, bahan terbiodegradasi dan platform pemantauan pelepasan berasaskan AI.