INCIT Strategic Partnership with AIDSMO to Accelerate Arab Industrial Transformation

INCIT Strategic Partnership with AIDSMO to Accelerate Arab Industrial Transformation The International Centre for Industrial Transformation (INCIT) is pleased to announce the signing of a cooperation agreement with the Arab Industrial Development, Standardization and Mining Organization (AIDSMO). The agreement was signed on 30 September 2025 in Ben Guerir, Morocco, during the NextGen Manufacturing Summit “Africa”, […]

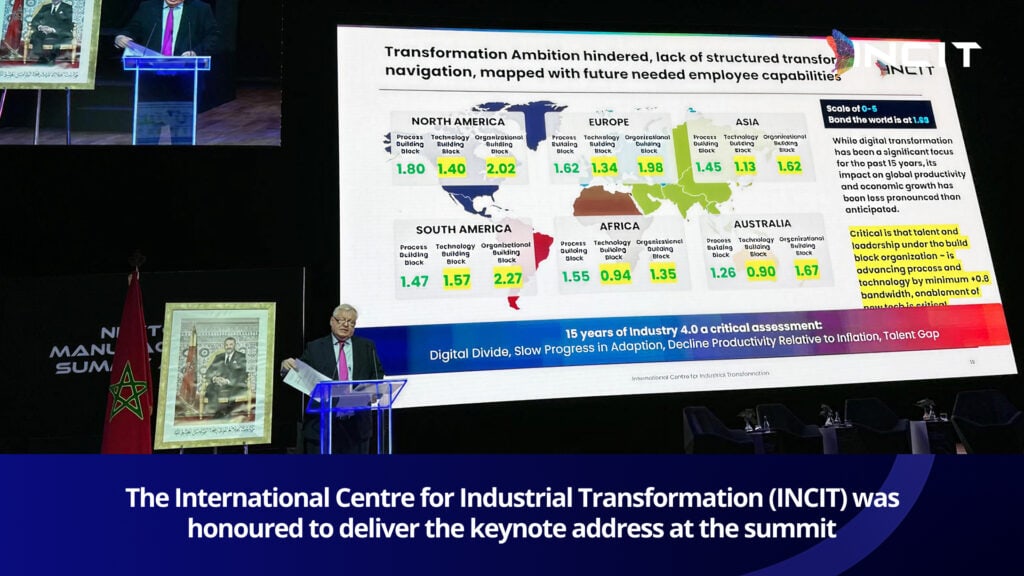

NextGen Manufacturing Summit Africa 2025: Africa 4.0: Shaping the Future of African Manufacturing

NextGen Manufacturing Summit Africa 2025: Africa 4.0: Shaping the Future of African Manufacturing The recent NextGen Manufacturing Summit Africa 2025 marked a defining moment for the continent’s industrial future, bringing together key stakeholders from across Africa and the globe to advance the vision of “Africa 4.0.” With over 1,200 participants attending in person and an […]

INCIT is honored to host an Indian Industry Delegation Visit comprising over 30 top business leaders at INCIT Singapore!

INCIT is honored to host an Indian Industry Delegation comprising over 30 top business leaders at INCIT Singapore! In a powerful demonstration of global collaboration and industrial innovation, the International Centre for Industrial Transformation (INCIT) had the distinct honor of hosting a distinguished delegation of over 30 top Indian business leaders in Singapore. The […]

Skill Kerala Global Summit 2025: Shaping the Future of Work and Talent

On 29–30 August 2025, Kochi became the centre of global dialogue on skills, innovation, and the future of work as it hosted the Skill Kerala Global Summit 2025. The landmark event brought together thought leaders, industry pioneers, policymakers, academics, entrepreneurs, and aspiring changemakers with a common ambition: to firmly establish Kerala as a premier destination […]

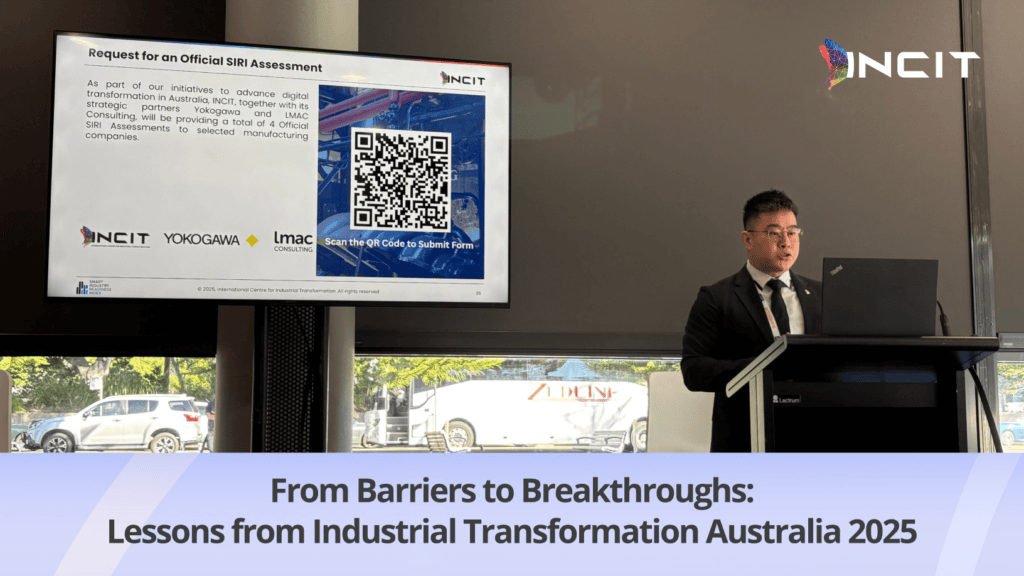

Removing the Barriers: Industrial Transformation Australia 2025 Recap

The Industrial Transformation in Australia – Removing the Barriers forum took place on 23 July 2025 at the Sydney Olympic Park, as part of Industrial Transformation Australia (ITA) 2025. Hosted by the Industry Capability Network (ICN) and supported by SeerPharma and the International Centre for Industrial Transformation (INCIT) through its thought leadership programme Global Executive […]

From Complexity to Clarity: INCIT Shares Decision-Driven Transformation Insights at TÜV SÜD China Seminar

As manufacturers race to digitalise, many find themselves stuck in the weeds: – 30% of transformation investments fail to deliver impact – 43% of smart production lines remain vulnerable to cyber threats – 20% of decisions are skewed due to poor data quality To address these pressing challenges, TÜV SÜD China convened the “TÜV SÜD […]

INCIT and Yokogawa Middle East & Africa Forge Strategic Partnership to Drive Industrial Transformation in the Gulf Region

Singapore – 18 June 2025 – The International Centre for Industrial Transformation (INCIT) and Yokogawa Middle East & Africa are pleased to announce the signing of a Strategic Collaboration Agreement to advance digital transformation initiatives across the Kingdom of Saudi Arabia, the Kingdom of Bahrain, and the Sultanate of Oman. This partnership aims to accelerate […]

Is Your Manufacturing Ready for Industry X.0 or Just Talking About It?

In an increasingly volatile global landscape, the manufacturing sector finds itself at a critical crossroads. Disruptions sparked by the pandemic, climate change, geopolitical tensions, and accelerating technological change have not only exposed vulnerabilities but also underscored the urgent need for transformation. For manufacturers seeking to build resilience and long-term competitiveness, digitalisation is no longer a […]

The Global Smart Industry Readiness Index (SIRI) Initiative: Manufacturing Transformation Insight Report 2025

As manufacturers face growing global pressures — from supply chain disruptions to climate imperatives and rapid technological change — transformation is no longer optional. This whitepaper presents insights from thousands of manufacturing companies across over 60 countries, revealing the key trends shaping the industry and the critical gap between strategic vision and operational execution. The […]

Hitachi and INCIT Partner to Advance Digital Transformation with Smart Industry Readiness Index (SIRI) and XIRI-Analytics

Singapore/Japan, March 26, 2025 – Hitachi, Ltd. (TSE: 6501, “Hitachi”) and International Centre for Industrial Transformation Ltd. (“INCIT”) announces today that Hitachi will partner with INCIT to implement Smart Industry Readiness Index (SIRI) and XIRI-Analytics to accelerate the digital transformation of Hitachi’s global manufacturing operations. In the next Mid-Term Management Plan, Hitachi aims to realise […]

Oman Builds Industrial Future with Key MoUs, INCIT to Drive Digital Transformation

Oman’s Industry Day, held on February 9, 2025, highlights the country’s industrial growth and future plans. Organized by the Ministry of Commerce, Industry, and Investment Promotion (MoCIIP), this year’s theme, “Oman at the Heart of Global Supply Chains,” reflects the nation’s role in global trade and manufacturing. The event brought together government officials, business leaders, […]

Transforming Egypt’s Manufacturing Sector with the Smart Industry Readiness Index

The future of manufacturing in Egypt is taking a transformative leap forward with the introduction of the Smart Industry Readiness Index. Developed to guide manufacturers of all sizes and sectors, Smart Industry Readiness Index is designed to help businesses start, scale, and sustain their digital transformation journeys. This pioneering initiative has been made possible through […]

Suzhou Industrial Park hosts Smart Industry Readiness Index training to accelerate Industry 4.0 advancements

[September 2024] – In collaboration with INCIT’s training and certification partner, TÜV SÜD, and the Bosch Empowerment Centre, the Suzhou Industrial Park (SIP) organised a Smart Industry Readiness Index training in September 2024. This initiative is designed to propel companies toward their Industry 4.0 and smart manufacturing goals. The organiser SIP, a joint venture between […]

Charting the course towards digital excellence with Akebono

As the global automotive industry adapts to the challenges posed by the pandemic, PT. Akebono Brake Astra Indonesia (AAIJ) is taking its digital transformation efforts to the next level with the Smart Industry Readiness Index. AAIJ is addressing the evolving demands in the brake pad sector by embracing innovative technologies and sustainable practices. By leveraging […]

Transforming industries with Yokogawa’s Certified SIRI Assessor

We are thrilled to announce the release of a new joint marketing film created in collaboration with our partner, Yokogawa Electric Corporation. With the highest number of CSAs in the world, Yokogawa’s dedication to the SIRI framework and their commitment to providing valuable solutions is unparalleled. This film is an excellent opportunity to see firsthand […]

SEW-EURODRIVE improves flexibility and raises productivity with Smart Industry Readiness Index

In a fast-changing world, companies need to be flexible and agile to survive and thrive. To achieve this, SEW-EURODRIVE needed to modernise its Singapore facility through the application of Industry 4.0. Committed to driving change and transformation to improve flexibility and raise productivity, SEW-EURODRIVE leveraged Smart Industry Readiness Index to work out focus areas so […]

Rockwell Automation drives sectorial transformation with Smart Industry Readiness Index

Rockwell Automation is the world’s largest company dedicated to industrial automation and information. Its mission is to improve global quality of life through smart manufacturing and digital transformation solutions – including architecture, software, and control products and solutions – that deliver enhanced productivity while maintaining environmental sustainability. Its Singapore-based subsidiary Rockwell Automation Asia Pacific Business […]

Smart Industry Readiness Index in the Spotlight: Validating Haier Group’s digitalisation programme

Haier Group undertook a multi-site Official Smart Industry Readiness Index Assessment to gain a deeper understanding of their facilities’ 4IR maturity levels. This assessment enabled Haier to uncover blind spots within their operations and benchmark their facilities’ Industry 4.0 transformation against industry standards and competitors. By pinpointing areas of strength and opportunities for improvement, Haier […]

Smart Industry Readiness Index in the Spotlight: Helping Pepperl+Fuchs set digital transformation targets

German industrial technology company Pepperl+Fuchs recently harnessed the power of the Smart Industry Readiness Index (SIRI) to assess the Fourth Industrial Revolution (4IR) readiness of multiple manufacturing sites. Through an Official Smart Industry Readiness Index Assessment, Pepperl+Fuchs discovered that one of their sites had a maturity profile that was below the industry average. The detailed […]

Smart Industry Readiness Index in the spotlight: How organisations and governments work together to jumpstart digital transformation in manufacturing

Multilateral organisations and governments can collaborate to help manufacturers on their digital transformation journeys.

CONNSTEP drives manufacturing transformation in Connecticut with Smart Industry Readiness Index

The manufacturing industry in Connecticut, USA has faced significant challenges in adopting Industry 4.0. A common perception is that transitioning to Industry 4.0 technologies is only feasible for larger companies, leaving many small and medium-sized enterprises (SMEs) with misconceptions about its goals and true potential. In a state where family-owned SMEs represent a substantial portion […]